The RhinoCAM Difference

“RhinoCAM is very intuitive to use and integrates seamlessly with Rhino. Our decision to upgrade RhinoCAM to its 5-axis Premium configuration is primarily due to its integration with Rhino as well as our experience with RhinoCAM for almost a decade. Our experience with AlphaCAM however, has been a difficult one.” David Wilson, Creative Director |

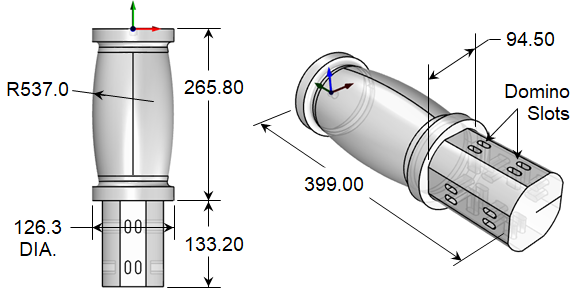

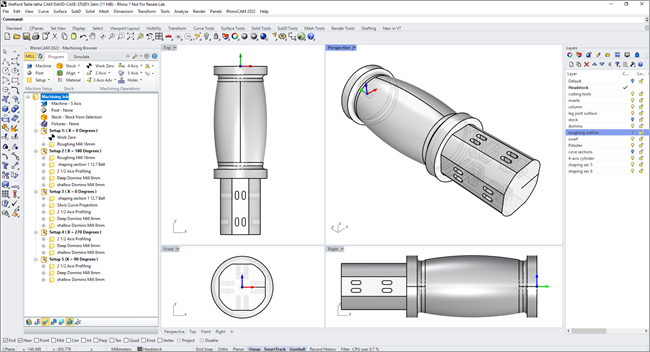

The RhinoCAM Part

The part David has chosen for this case study is shown below. It is the center pedestal for one of their bespoke center table designs. The piece is cut from poplar and measures approximately 400 mm long and 125 mm in diameter. The completed table is a traditional hall table made in walnut with a burr/burl walnut veneered top and ebony stringing. While the part is typically 4-axis, David used their Bacci 5-axis machining center to cut the piece without issues. The part is illustrated below.

The RhinoCAM BACCI Programmable Post-Processor

BACCI 5 Axis Videos

The Final Product

Cool project David!!

Thank you for allowing us to showcase your work!

A complete line of CNC machining centers has been developed by the company, all equipped with the latest technology and software. From chair manufacturing to tables, doors, windows, and furniture components in general, all the way to the manufacturing of plastic, aluminum, and composite elements, this new line of machines has a wide range of applications.

More Pics from Dovetailors