MK Fabrication, a sister company of General Fence, Inc., is a growing full service fabrication shop with mobile capability. Built on quality and customer service, they work on everything from Mining and Heavy Equipment to backyard projects. The ability to manufacture its own custom tooling makes their clients’ jobs easier, faster, and more cost effectuive. Read more About MK Fabrication later in this case study.

The RhinoCAM Part

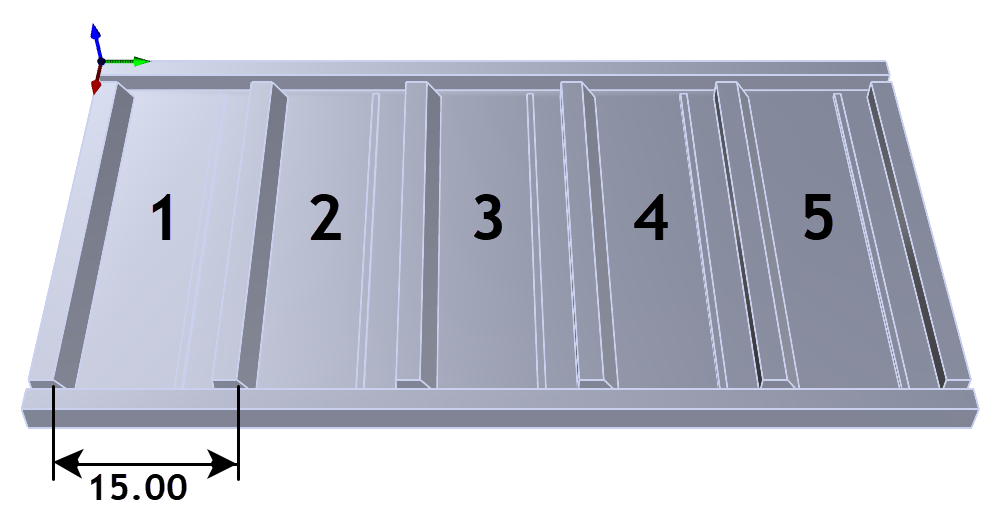

The part features for this case study are mostly prismatic, meaning that they are 2-dimensional with vertical walls. One feature however, has a sloped contour shape. There is a pocket on each side that cuts completely through the part. The part also has five identical sets of features as shown in the illustration below.

XY Instance Operation

In RhinoCAM you can instance toolpath operations if you have identical part features to machine. In our part we see that there are 5 identical sets of part features. They are identified in the illustration below. The toolpath operations shown in the Machining Job tree below are for feature set #1. There are 4 more identical feature sets each being 15.00” apart along the Y axis. We are using RhinoCAM Professional’s XY Instance operation to do this.

Selecting the XY Instance command from the Other Miscellaneous Operations menu will display the XY Instance Operation dialog shown below. The dialog allows you to enter the spacing of the instances as well as the number of instances. In our case we want 4 copies spaced 15.00” apart along the Y Axis.

When you pick Generate, the XY Instance is created and added to the Machining Job as a folder named XY Instance. You can rename this folder if you like. Now, with the XY Instance created, we just have to drag-and-drop each of our existing toolpath operations into this folder. Then, selecting the XY Instance folder will display the 4 additional instanced copies. This is shown in the RhinoCAM display below.

Post-Processing GCode

During post-processing, each instance of each toolpath operation is commented on in the gcode file as shown below. Optionally, you can post-process one or more specific operations. Options also available to post operations based tool number.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.