CAM Software

CAM Software Details

CAM Software Explained

CAM Software

CAM Software

MecSoft has several CAM Software products to meet your needs. Whether you’re looking for a standalone CAM software package, or a CAM software package that fully integrates into a powerful CAD program, MecSoft has a solution for you. Click on a CAM software solution to learn more! For questions regarding any of our CAM software solutions, please do not hesitate to contact us.

CAM Software Details

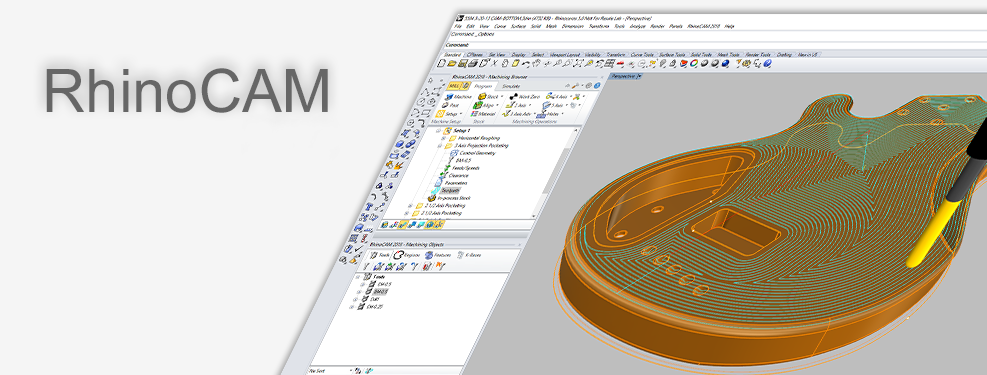

RhinoCAM

RhinoCAM is a Computer Aided Machining (CAM) plug-in for CNC that runs completely inside of Rhinoceros 5.0 & 6.0. This plug-in is a general purpose machining program targeted at the general machinist. RhinoCAM marries the power of Rhino’s freeform modeling with the legendary machining capabilities of VisualCAM to bring you a product of unrivaled capability for free form surface machining. With the seamless user interface, selection and display integration RhinoCAM acts and feels like you are working with Rhino when creating your cutter paths.

RhinoCAM is fully associative to any geometry changes within Rhino. RhinoCAM includes modules for MILL, TURN, NEST, ART and MESH to address specific needs of various CNC manufacturing processes.

VisualCAD/CAM

VisualCAM along with VisualCAD is MecSoft’s standalone CAD/CAM package that is considered the best valued CAD/CAM system on the market today. VisualCAD/CAM features MecSoft’s FREE and easy-to-use CAD program VisualCAD. VisualCAM is MecSoft’s flagship CAM software product that addresses the CNC machining market needs with modules VisualMILL, VisualTURN, VisualNEST, and VisualART to address specific needs of various CNC manufacturing processes.

CAM Software Explained

What is CAM Software?

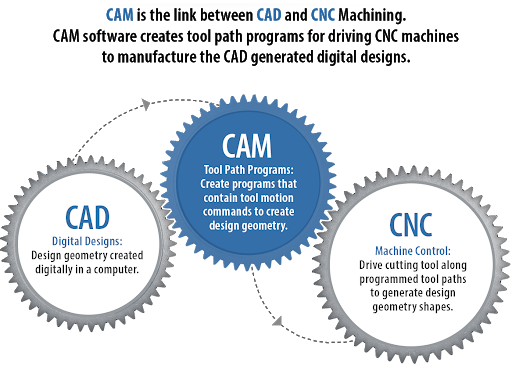

CAM or Computer Aided Manufacturing software used to create machine programs to control CNC machine tools for manufacturing parts in a wide variety of industries. A CAM software system can be considered as an off-line programming system for programming CNC machine tools. The term off-line is used to indicate that the programming is done is the CAM system that is not digitally connected to any CNC machine tools. The most common codes used in these CNC machine programs are ISO standard G & M codes.

CAM Software systems are not employed in isolation but are an essential and integral part of CAD/CAM/CNC systems. CAM systems are used to read in digital designs created by CAD systems and to create machine control programs for CNC machines. This inter-dependence of these systems is depicted below.

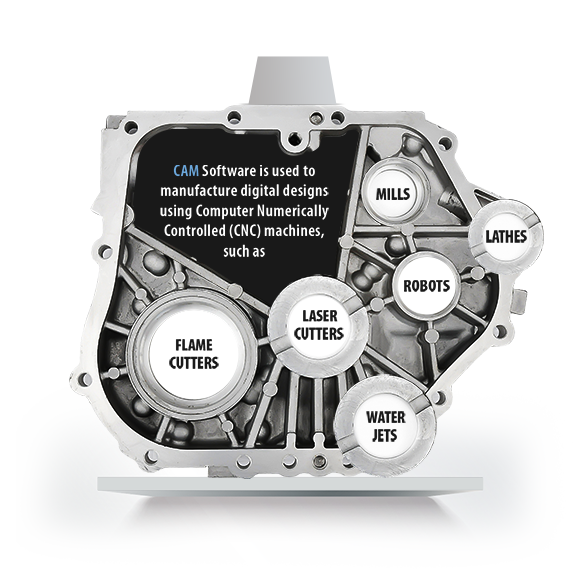

Machining Processes addressed by CAM Software

Milling, Turning and Drilling are the most common machining processes addressed by CAM software. Most CAM software can also be used to program other cutting machines such as EDM machines, Plasma cutters, Water jet cutters.

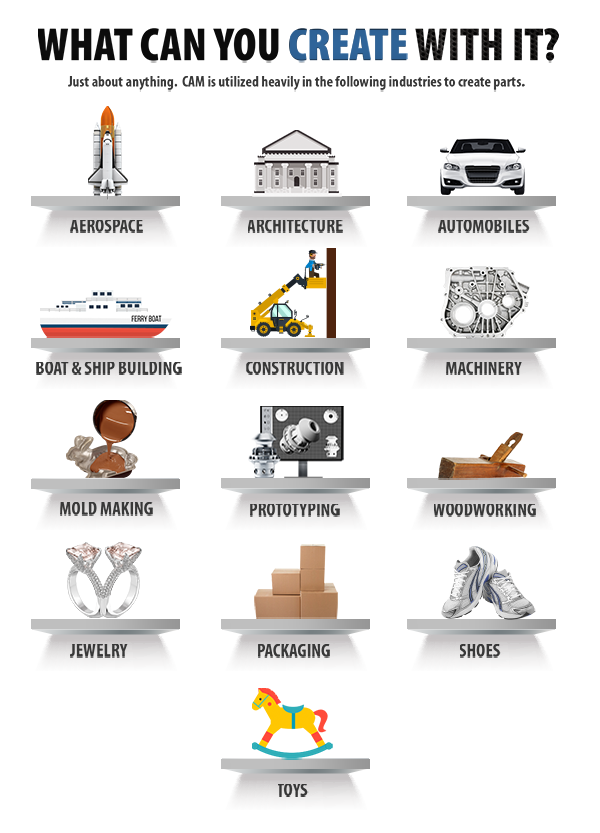

Applications of CAM Software

CAM software is used to manufacture parts in virtually every modern manufacturing industry that requires precision, high quality surface finish, repeatability and automation in machining. This includes just about every manufacturing industry such as Aerospace, Automotive, Machine Design, Architecture, Boat & Ship Building, Construction, Machinery, Mold & Die, Prototyping, Woodworking, Jewelry, Packaging, Consumer Goods, etc.