VisualMESH

VisualMESH

VisualMESH offers efficient, easy & automatic tools for cleaning up, reducing, refining and preparing 3D mesh data for downstream applications such as NC machining and 3D Printing. The seamless combination of VisualCAD’s file import functionality with VisualMESH’s data preparation tools enables the user to create clean, precise and water-tight mesh models from almost any major 3D format.

Use the following resources to get started with VisualMESH:

Work your way through the tutorials in the Quick Start Guide

Feature List

The table below summarizes the various features found in each of the available configurations of VisualMESH.

| USER INTERFACE | |

|---|---|

| Dock-able Browser | Browser window for easy access to MESH objects |

| Ribbon Interface | Ribbon interface for easy access to all VisualMESH functions |

| Dialogs in Browser | Split browser window to house function dialogs to relieve screen clutter |

| CREATION FUNCTIONS | |

|---|---|

| Meshes from Point Clouds | Create meshes from raw point clouds |

| MODELING FUNCTIONS | |

|---|---|

| Boolean Unite | Perform unite operations on multiple meshes |

| Boolean Subtract | Subtract one set of meshes from another |

| Boolean Intersect | Intersect two sets of meshes |

| Intersect & Split Meshes | Intersect one set of meshes with another and split them at the intersections |

| Split Meshes | Split meshes with virtual planes |

| Offset Meshes | Offset meshes to create shells |

| Convex Hull | Create the convex hull of selected meshes |

| Local Manipulations | Graphically modify local areas of a mesh using a manipulator |

| INSPECTION FUNCTIONS | |

|---|---|

| Reflection Lines Analysis | Use reflection line analysis to check quality of mesh |

| Curvature Analysis | Use curvature analysis to graphically examine areas of curvature |

| Compare Meshes | Compare two meshes and graphically display deviations between them |

| MODIFICATION FUNCTIONS | |

|---|---|

| Mesh Decimation | Reduce locally/globally the triangle count of meshes |

| Re-meshing | Re-mesh locally/globally to create uniform triangles |

| Smoothing of Meshes | Smooth meshes locally/globally to even out irregularities in data |

| REPAIR FUNCTIONS | |

|---|---|

| Stitch & Close | Stitch and close multiple meshes |

| Auto-fix | Automatically analyze and close holes in open meshes |

| Manual-fix | Detect holes fix them individually using different parameters |

| Diagnose | Perform a series of diagnostic checks on meshes |

| Separate Meshes | Separate meshes to independent bodies |

| Fix Orientation | Unify the orientation of all triangles in selected meshes |

| Flip Orientation | Reverse the orientation of all triangles in selected meshes |

| 3D PRINT FUNCTIONS | |

|---|---|

| Best Orientation | Find best orientation for printing based on minimum overhang areas |

| Generate Supports | Create supports for overhang areas before printing |

| Select 3D Printer | Select from a customizable list of 3D printers |

| Fit in 3D Printer Volume | Fit selected meshes inside the selected printer volume |

| 3D Print Checks | Perform a series of 3D print checks such as thin wall analysis |

| Export | Export selected meshes to STL or AMF format files |

| 3D Print using Win Drivers | Use the Win 8.1 drivers to send data directly to the 3D printer |

| Generate G-Code | Create nozzle paths and corresponding G-code for FDM/SLA printers |

Blog & News

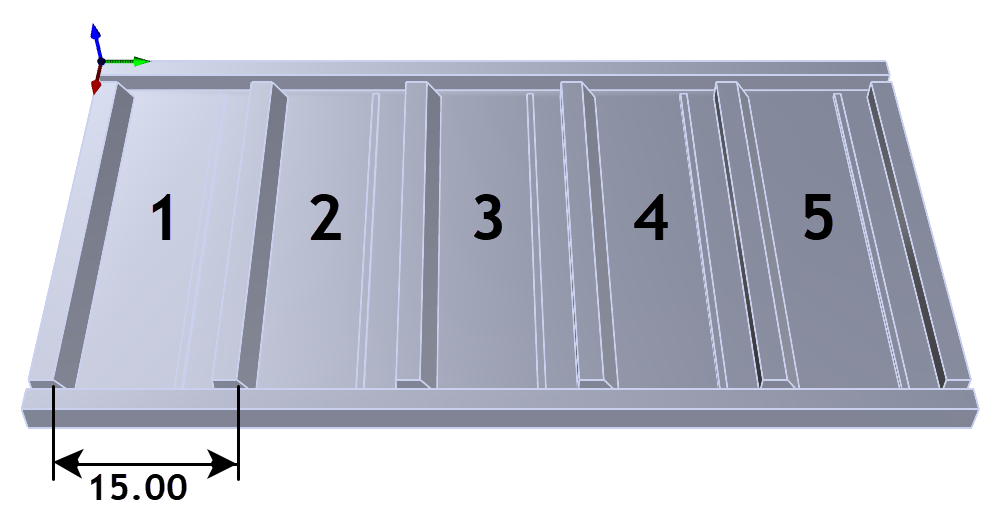

XY Instancing in RhinoCAM

MK Fabrication, a sister company of General Fence, Inc., is a growing full service fabrication shop with mobile capability. Built on quality and customer service,

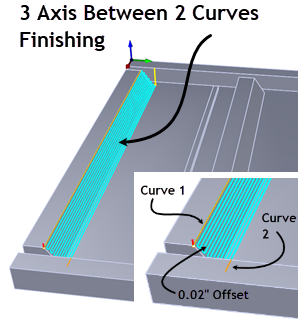

RhinoCAM at MK Fabrication

MK Fabrication, a sister company of General Fence, Inc., is a growing full service fabrication shop with mobile capability. Built on quality and customer service,

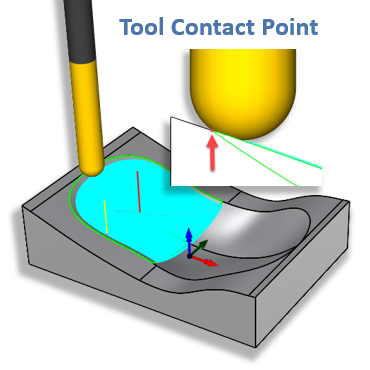

What’s New in MecSoft CAM 2024

With the release of RhinoCAM 2024 and VisualCAD/CAM 2024, new functionality and changes are being introduced. We have improved the quality of our product with