Understanding how to machine 2-sided parts is a concept difficult to grasp for many new CAM users. The more complex the part, the more this process is relied upon for a successful machining job. There are different approaches. All of the reliable methods will involve two or more dowel pins.

Jeff Kozmoski of KOZM Guitars has a reliable technique that he is happy to share with other users; we have documented it below. It involves two ¼” dowel pins. However, Jeff mounts the dowel pins to the part itself as well as to a base fixture plate. His technique holds the stock firm without having to leave tabs holding the part and stock together. Follow the illustrations below to understand this technique. You can also watch the video.

Jeff Kozmoski of KOZM Guitars has a reliable technique that he is happy to share with other users; we have documented it below. It involves two ¼” dowel pins. However, Jeff mounts the dowel pins to the part itself as well as to a base fixture plate. His technique holds the stock firm without having to leave tabs holding the part and stock together. Follow the illustrations below to understand this technique. You can also watch the video.

Stock blanks are cut from sheet stock.

The stock blanks are glued together and mounted to the CNC router bed.

The top side of the guitar body is machined without leaving any stock tabs.

Here we see a view of the top machined side of the guitar body.

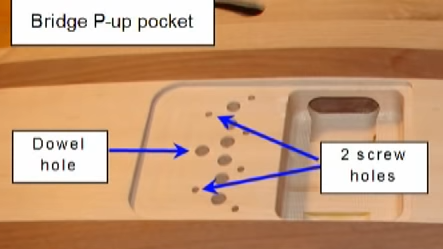

¼” dowel pin holes and screw mounting holes are machined on the bridge area.

¼” dowel pin holes and screw mounting holes are machined on the neck area as well.

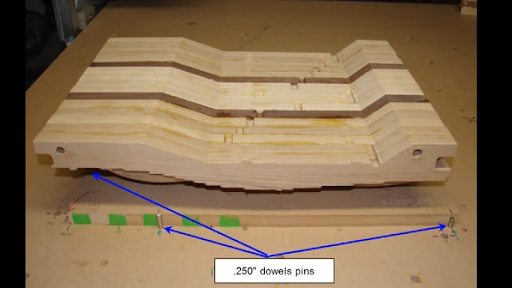

Two fixture blocks and a fixture plate are prepared with ¼” dowels and screw mounting holes.

The fixture blocks are mounted to the top side of the machined guitar body using the dowels.

The fixture plate is mounted to the fixture blocks using the dowel pins for alignment.

The fixture plate is flipped over and aligned and mounted to the CNC router bed.

With the fixture plate mounted, the back side of the guitar is machined.

Here we see the fully machined guitar body ready to be removed from the fixture plate.

The completed guitar body top

The completed guitar body bottom.

(M)

The Machine Zero: The dowel pin hole on the neck serves as the Work Zero for machining the top side. The same dowel pin location on the fixture plate is used to zero the machine for cutting the bottom side. Hat’s off to Jeff for designing this excellent “flip-machining” technique!

The Machine Zero: The dowel pin hole on the neck serves as the Work Zero for machining the top side. The same dowel pin location on the fixture plate is used to zero the machine for cutting the bottom side. Hat’s off to Jeff for designing this excellent “flip-machining” technique!

About Jeff Kosmoski

Jeff Komoski is a Mechanical Engineer who has used various CAD packages in his day jobs since the early 80s. These have included Unigraphics, CADKEY, ProE / Creo, Solidworks, and most recently, NX. Jeff currently works for ThermoFisher Scientific, working on electron microscopes and ion-generating columns. Jeff also has experience in numerous product arenas including Aerospace, Medical, Robotics, Color Printers, Scientific Instruments as well as Consumer Products.

Cool Designs from KOZM Guitars!

More about KOZM Guitars

You can learn more about Jeff Kosmoski and KOZM Guitars by visiting his website at www.kozmguitars.com. To learn more about Jeff’s CNC process you can visit the Digital Lutherie page. We want to extend a special thanks to Jeff Kosmoski for allowing us to showcase his work!

Cool project Jeff!

Thank you for allowing us to showcase your work!

Thank you for allowing us to showcase your work!