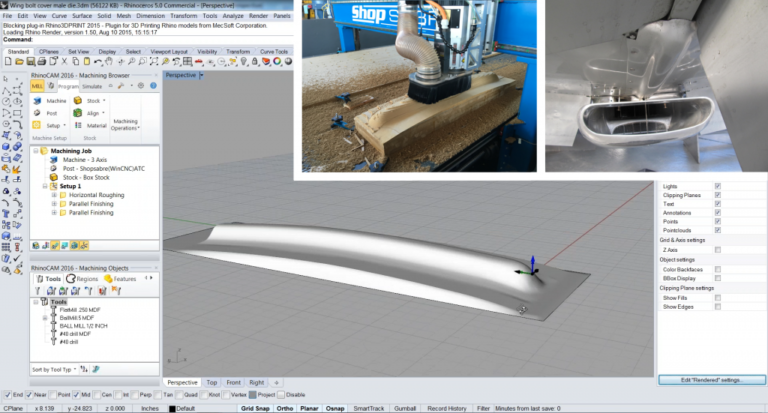

AirMotive Specialties, Inc. (Salinas, CA) is well known in aviation circles worldwide for its quality restorations of vintage WWII-era aircraft such as the P51 Mustang Fighter aircraft shown here. This effort in many cases requires reverse engineering the original aircraft components.

AirMotive relies on RhinoCAM and their ShopSabre CNC router to manufacture many of these components including the form-press dies they use to manufacture the aerodynamic skin panels of the aircraft. An example of one of these dies in shown below.

Main Image: Bolt Cover Skin Panel from the P51 Mustang Fighter Bomber modeled in Rhino with the RhinoCAM plugin loaded. 3 Axis Roughing and Finishing operations are displayed in the Machining Job tree.

Inset Left: The Bolt Cover positive die is being machined from the RhinoCAM toolpaths on AirMotive’s ShopSabre CNC.

Inset Right: The resulting Bolt Cover Skin Panel is shown mounted on an actual P51 Mustang.