We appreciated this case study provided by Philipp Außem. Enjoy!

CAD and CAM processes play a major role in my Industrial Product Design Studies. However, I did not know how to combine these two steps of the designing process and the CNC machining process into a continuous work flow. To learn more about this, I participated in some practical training at ehlersdesign in Munich.

Picture 1: Milling of the side parts with holes for plain bearings of the rods, ball throw-in, hooks for connectors.

Ehlersdesign specializes in 3D milling and produces almost everything from wax molds for jewelry designers, architectural modeling for trade fair constructors, to custom projects using 2- through 4-axis machining. To generate the milling data, Ralf Ehlers uses RhinoCAM, a plug-in for Rhinoceros. This CAM solution appears as a browser within Rhino and allows skipping the export or import of geometry data, thus saving time and effort.

Although I haven’t used Rhino for a long time and have never used RhinoCAM before, the uncomplicated setup and user friendly interface of the program make it easy to use.

We appreciated this case study provided by Philipp Außem. Enjoy!

CAD and CAM processes play a major role in my Industrial Product Design Studies. However, I did not know how to combine these two steps of the designing process and the CNC machining process into a continuous work flow. To learn more about this, I participated in some practical training at ehlersdesign in Munich.

Picture 1: Milling of the side parts with holes for plain bearings of the rods, ball throw-in, hooks for connectors.

Ehlersdesign specializes in 3D milling and produces almost everything from wax molds for jewelry designers, architectural modeling for trade fair constructors, to custom projects using 2- through 4-axis machining. To generate the milling data, Ralf Ehlers uses RhinoCAM, a plug-in for Rhinoceros. This CAM solution appears as a browser within Rhino and allows skipping the export or import of geometry data, thus saving time and effort.

Although I haven’t used Rhino for a long time and have never used RhinoCAM before, the uncomplicated setup and user friendly interface of the program make it easy to use. Table Soccer

In RhinoCAM, the first step after opening the machine operations browser is to create a stock model which is the digital equivalent to the milling material. The next step is to select the milling region. For this purpose you simply use the line tool of the CAD software to markup the milling area with straight and curved lines.

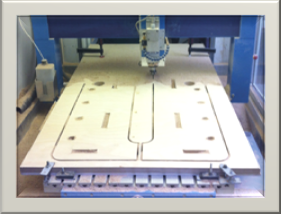

Picture 2: Fitting of the playing field which was delivered oversized. For our purposes we needed exactly 1200 x 680mm.

The next steps for 3-axis 3D processing, such as roughing (rough material removal) and finishing (fine material removal to size), are self-explanatory and are shown in the menu supported by small graphics.

Picture 3: Finishing of the ball catcher with slanted floor so that the ball will roll into the free space and can be taken out.

A tool library can be loaded for selecting the milling tools, where every single milling cutter can be opened and edited.

Once the milling paths are ready, there is an additional simulation function in RhinoCAM, which generates a digital presentation of the milling process and shows the result as a colored 3D form. This feature helps to verify the programmed milling paths repeatedly.

Picture 4: Finished goal construction with wooden ball catcher and curved Plexiglas. On the right is the ball storage.

When all settings are checked and simulation is successful, RhinoCAM will convert or ‘post process’ the milling data to the milling program for the machine. This is done by transforming the CAM milling path into motion and functional codes that are required by the machine tool.

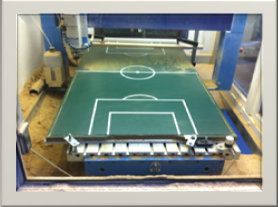

Pictures 5 & 6: The finished prototype of the table soccer featuring screw-free assembly.

In this way, RhinoCAM allows completion of all steps starting from the 3D model to the transfer of the codes to the milling machine with a budget-friendly and reliable application.

This table soccer is designed to be different from others of this family both in appearance and function. The basic idea is that it is just assembled through plug-in connections, e.g. slots and hooks. The idea is to allow easy assembly and disassembly without any screws and to get it ready for easy transportation. Nevertheless, it should give the feeling of an authentic playing experience at a real tournament table.

The Splash Gun Toy

The Splash-Gun is a toy for kids. It includes a PET bottle (inside the yellow rocket), half filled with water that is connected to a pump. Repeated pumping will produce high pressure that will release and propel the yellow rocket through the air. This is the same principle for a rocket lifted vertically into the air, whereas this rocket is designed for horizontal flight.

When extending the pump, the air is sucked between piston rod and pipe cover, crosses the gasket and finally enters the PMMA pipe. When compressed, the piston seal closes inside the PMMA pipe as it only allows passing the air inside and is being pressed against the walls because of the air pressure which develops inside the pipe. The check valve (which is the function of the rubber ball with the spring) presses the air through the piston into the bottle. By repeated pumping, a pressure of 4 bar (58 psi) can be built up in the bottle. This pressure was safety tested with the existing rubber seal, check valve, bottle, and air pump.

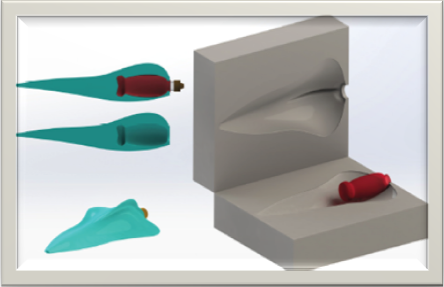

The model of the polyurethane rocket is formed in the cavity of this machined mold.

These pictures show the mold cavity, inside of which the foam will expand to form the polyurethane rocket model. The mold cavities are cut on a CNC machine.

The PET bottle inside the polyurethane foam serves as the pressure tank.

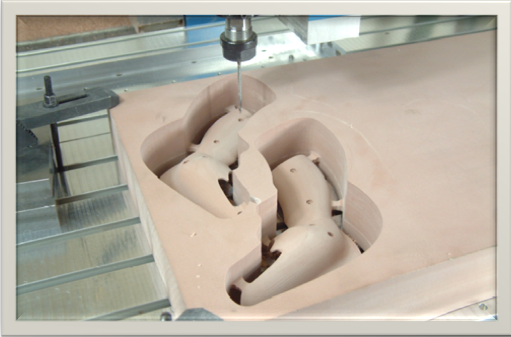

These pictures show milling of the prototype handle as two half-shells. The parts are milled with 3D roughing (on top, the inner surfaces with reinforced walls) and finishing (at the bottom, the outer surfaces). The milling codes were generated with RhinoCAM.