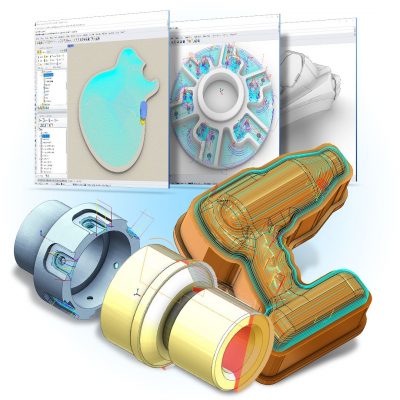

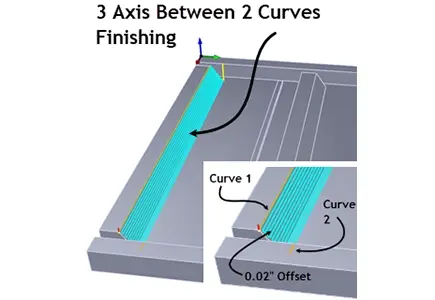

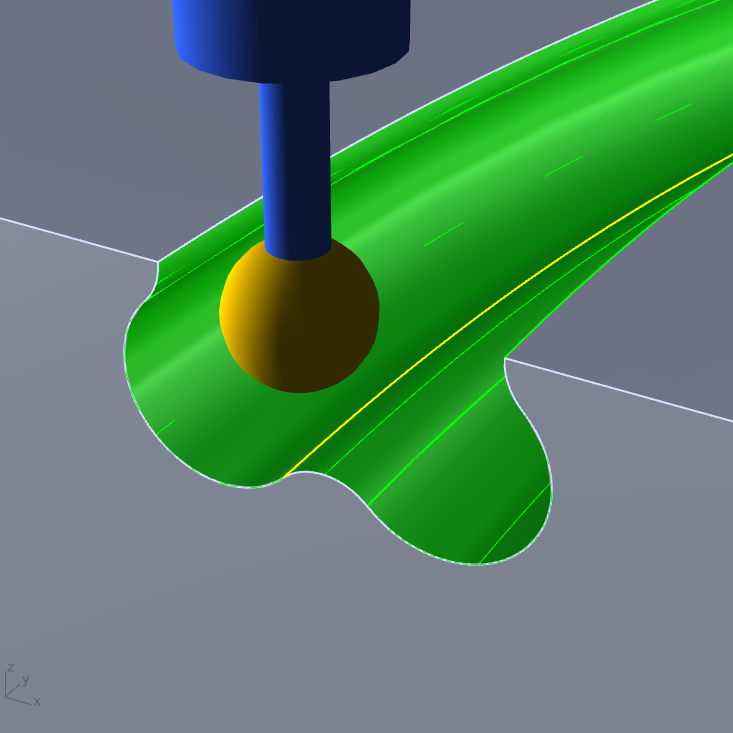

Since 1997, MecSoft Corporation has been developing, marketing, and supporting standalone CAM software, as well as CAD/CAM software solutions for CNC machining. Our Rhino integrated RhinoCAM and stand-alone VisualCAD/CAM products are not only easy to use but are also powerful and affordable. Please take your time to peruse our website for additional information, download and run our fully functional demo products, or give us a call if you have any questions.

#1 CAM SOFTWARE IN OVER 50 COUNTRIES

With thousands of users worldwide, our customers range from small and medium sized businesses to large Fortune 50 companies. Each of these customers has come to rely on our CAD/CAM products, products that have undergone decades of meticulous development and rigorous production testing, to provide proven and dependable results to keep their manufacturing operations humming.

https://www.high-endrolex.com/21