RhinoCAM-MILL

RhinoCAM-MILL

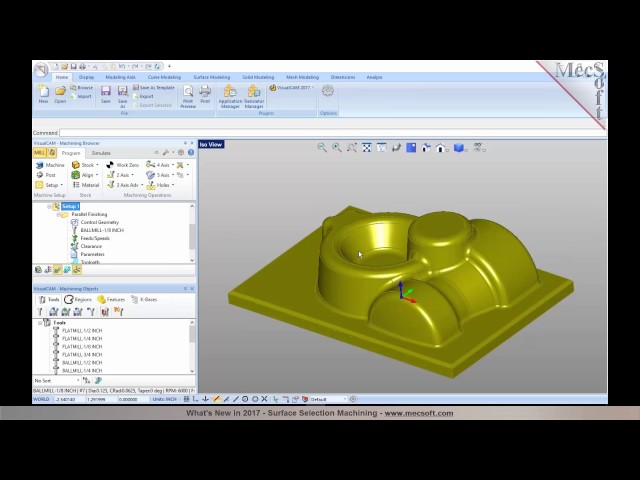

RhinoCAM-MILL is one of the five modules offered in the RhinoCAM CAM software suite. Combining free-form modeling power of Rhino and the legendary machining capabilities of VisualMILL this module offers an easy to use yet powerful milling solution that is ideal for mold, die & tooling, wood working, rapid-prototyping and general machining. RhinoCAM includes 2-1/2, 3, 4 & 5 axis machining functionality. It comes with hundreds of free post-processors and a post-processor generator to create your own. Priced right for the cost conscious buyer, RhinoCAM-MILL CAM software delivers outstanding value for your investment.

Use the following resources to get started with RhinoCAM – MILL:

Learn about the new features in RhinoCAM 2024

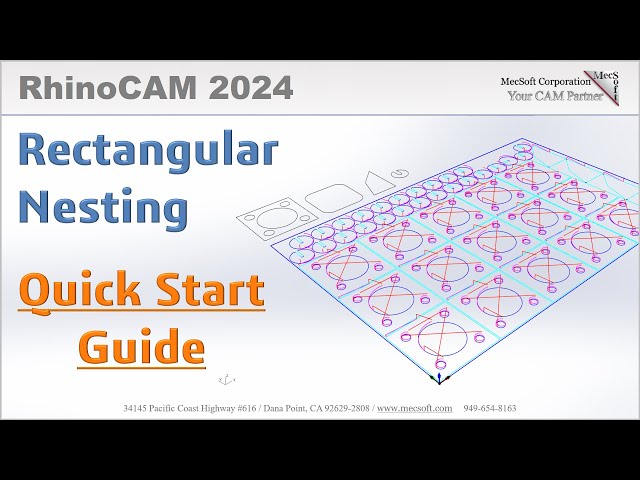

RhinoCAM-MILL Quick Start Guide Document

RhinoCAM – MILL Quick Start Videos

RhinoCAM – MILL Golden Oldies

Feature List

RhinoCAM-MILL, our flag-ship CAM software package, is ideal for mold, die & tooling, wood working, rapid-prototyping and general machining.

| 2 1/2-AXIS MILLING | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| Pocketing |

|||||

| Profiling |

|||||

| Facing |

|||||

| Engraving |

|||||

| V-Carving |

|||||

| V-Carve Roughing |

|||||

| 2-1/2 Axis Feature Detection | |||||

| 2-1/2 Axis Feature Machining | |||||

| 2-1/2 Axis Roughing | |||||

| High Speed Pocketing | |||||

| Chamfering |

|||||

| Hole Profiling | |||||

| Hole Pocketing |

|||||

| T-Slot Milling | |||||

| Slot Milling | |||||

| Thread Milling |

|||||

| Drag & Rotary Knife Cutting | |||||

| Saw Machining | |||||

| Re-Machining |

| 3 AXIS MILLING | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| Horizontal Roughing | |||||

| Parallel Finishing | |||||

| 3 Axis Feature Detection | |||||

| 3 Axis Feature Machining | |||||

| Horizontal Finishing | |||||

| Radial Machining | |||||

| Spiral Machining | |||||

| Clear Flats Machining | |||||

| Plunge Roughing | |||||

| Horizontal Re-roughing | |||||

| Plunge Re-roughing | |||||

| Projection Pocketing | |||||

| 3D Offset Profiling | |||||

| 3D Offset Pocketing | |||||

| Pencil Tracing | |||||

| Valley Re-Machining | |||||

| Plateau Machining | |||||

| Steep Area Parallel Machining | |||||

| Horizontal Hill Machining | |||||

| Curve Machining | |||||

| Between 2 Curves Machining | |||||

| Reverse Post Machining |

| 4 AXIS MILLING | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| 4 Axis Indexed Machining | |||||

| 4 Axis Auto Multiple Indexing | |||||

| 4 Axis Continuous Facing | |||||

| 4 Axis Continuous Pocketing | |||||

| 4 Axis Continuous Profiling | |||||

| 4 Axis Continuous Engraving | |||||

| 4 Axis Parallel Roughing | |||||

| 4 Axis Parallel Finishing | |||||

| 4 Axis Radial Finishing | |||||

| 4 Axis Projection Pocketing | |||||

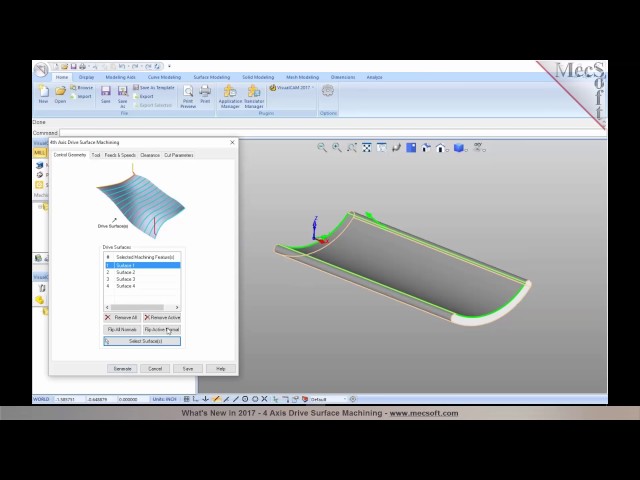

| 4 Axis Drive Surface Machining (True 4 Axis) |

| 5 AXIS MILLING | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| 5 Axis Indexed Machining | |||||

| 5 Axis Curve Projection Machining | |||||

| 5 Axis Continuous Flow Curve Machining | |||||

| 5 Axis Between 2 Curves Machining | |||||

| 5 Axis Drive Curve Machining | |||||

| 5 Axis Surface Normal Machining | |||||

| 5 Axis Swarf Machining |

| HOLE MAKING | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| Automatic Hole Selection, Sorting | |||||

| Drilling | |||||

| Tapping | |||||

| Boring | |||||

| Reverse Boring | |||||

| User Defined Cycles | |||||

| 4 Axis Drilling | |||||

| 4 Axis Tapping | |||||

| 4 Axis Boring | |||||

| 4 Axis Reverse Boring |

| SIMULATION | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| Toolpath Animation | |||||

| Cut Material Simulation | |||||

| Advanced Cut Material Simulation | |||||

| Visual Holder Collision Detection | |||||

| Machine Tool Simulation |

| TOOLS | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| Standard Tools (Ball, Flat, C Rad., Vee, Drill) | |||||

| Advanced Tools (Taper,Tap,Bore,R.Bore) | |||||

| Form Tools | |||||

| Stepped Tools | |||||

| Analytical Holder Collision Detection |

| TOOLPATH EDITING | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| Toolpath Graphical Viewing | |||||

| Toolpath Graphical Editing | |||||

| Toolpath Instancing | |||||

| Toolpath Arc Fitting |

| POST PROCESSOR GENERATOR | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| Customizable Post Generator | |||||

| Simulate Cycles | |||||

| Arc Output | |||||

| Helix Output | |||||

| Spiral Output | |||||

| 5 Axis Output |

| MISCELLANEOUS | XPR | SDT | EXP | PRO | PRE |

|---|---|---|---|---|---|

| 64 Bit | |||||

| HTML Shop Documentation | |||||

| Avoid Regions | |||||

| Predefined Regions | |||||

| Default Knowledge Base | |||||

| Machine Control Operations | |||||

| Cabinet Design Decomposition | |||||

| Rotate Table Setups | |||||

| Multiple Setups | |||||

| Fixture Offset Programming | |||||

| Check Surface Boundary Creation | |||||

| Tool Silhouette Boundary Creation | |||||

| Tool Double Contact Boundary Creation | |||||

| Tool Holder Collision Boundary Creation |