The RhinoCAM Difference!

![]() Because RhinoCAM works inside of Rhino. We do not need to export, import… That means if we change the project design, we can update the toolpaths in one click! Another important issue is that RhinoCAM is so intuitive. That helps a lot for students that are not familiar with CAM technology. And finally, support and feedback! Every time I need some help, the MecSoft support answers my questions very quickly!

Because RhinoCAM works inside of Rhino. We do not need to export, import… That means if we change the project design, we can update the toolpaths in one click! Another important issue is that RhinoCAM is so intuitive. That helps a lot for students that are not familiar with CAM technology. And finally, support and feedback! Every time I need some help, the MecSoft support answers my questions very quickly!

prof. arq. Affonso Orciuoli – Distribuidor Autorizado McNeel Brasil

McNeel & Associates, Kirkland, Washington

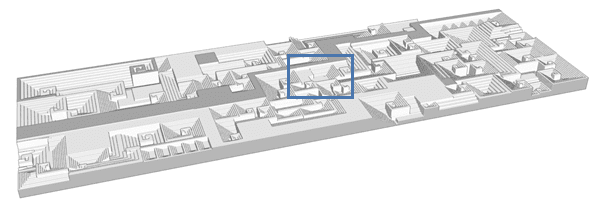

The “MAZE” Project

Here is a very cool video produced by the staff and students involved in this project:

“THE MAZE” Prof. arq. Affonso Orciuoli, Associate Professor | Research Assistant Architecture’s Gr…

The CAD Geometry

The Stock & Setup

Add Your Heading Text Here

The stock material for this project is medium density foam measuring 1480 x 510 x 40 millimeters (approx 60 x 13 x 1 inches and is defined as a Part Box Stock in RhinoCAM. This means that the stock dimensions are extracted from the bounding box dimensions of the part geometry. The Post-processor is set to Mach3-MM. The Machine is set to 3 Axis, no Fixtures are defined and there is one setup called Setup 1. This information is defined by the first 4 objects listed in the Machining Job as shown here.

Sequence of Operations

The next item in the Machining Job is a MOp Set. This is short for a Machining Operation Set. Operations can be grouped when they are similar or when they use the same cutting tool. The operations in the MOp Set are three 2½ Axis Pocketing operations each using a 4mm diameter flat end mill cutter. These pockets are locating channels for the three 3D Printed attachments shown in the final images below.

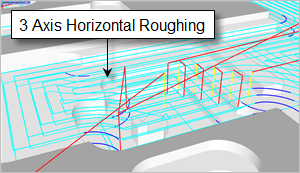

3 Axis Horizontal Roughing (20 Dia FM)

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

3 Axis Parallel Finishing (4 Dia FM)

![]()

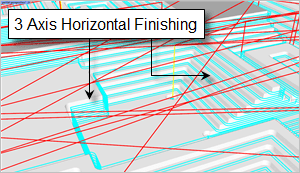

What is Scalloping and How to Avoid it?

A Scallop is material that is left after a machining operation. It is a result of the stepover distance being too large in relation to the cutter diameter. Scalloping can occur w hen a ball mill cuts geometry that is not vertical or when an end mill cuts geometry that is vertical. To minimize scalloping use a smaller stepover. In this case we can eliminate it by using 3 Axis Horizontal Finishing operation.

3 Axis Horizontal Finishing (4 Dia FM)

For Cut Control the cut direction is set to Climb, the Stepdown (dZ) is set to 2mm and Cut Levels Ordering is set to Depth First. This means that every pocket is cut to depth before moving on to the next. Entry and Exit is set to None so the tool will plunge from the clearance plane to engage and then retract to the clearance plane to end the cut motion.

2 1/2 Axis Pocketing (4 Dia FM)

Cool Teacher/Student project Pete!

Thank you for allowing us to showcase your work!

More About Affonso Orciuoli

More about RhinoCAM

RhinoCAM – MILL from MecSoft Corporation is available in five different configurations (Express, Standard, Expert, Professional and Premium). The part shown here was programmed using the Standard configuration. Here are some additional details about each of the available configurations. For the complete features list, visit the RhinoCAM Product Page.

- RhinoCAM MILL Express: This is a general-purpose program tailored for hobbyists, makers and students. Ideal for getting started with CAM programming. Includes 2 & 3 axis machining methods. Includes ART & NEST modules as well!

- RhinoCAM MILL Standard: This configuration includes everything that is in the Express configuration and additional 2-1/2 Axis, 3 Axis & Drilling machining methods. Also now includes 2½ Axis Turning!

- RhinoCAM MILL Expert: Suitable for 4 Axis rotary machining. Includes the Standard configuration, plus 4 Axis machining strategies, advanced cut material simulation and tool holder collision detection.

- RhinoCAM MILL Professional: Ideal for complex 3D machining. Includes the Standard and Expert configuration, plus advanced 3 Axis machining strategies, 5 Axis indexed machining, machine tool simulation, graphical toolpath editing and a host of other features.

- RhinoCAM MILL Premium: Tailored for complex 3D machining with both 3 Axis and full 5 Axis methods. Includes the Standard, Expert and Professional configurations, plus 5 Axis simultaneous machining strategies.

For the complete features list, we invite you to visit the RhinoCAM Product Page: mecsoft.com/rhinocam