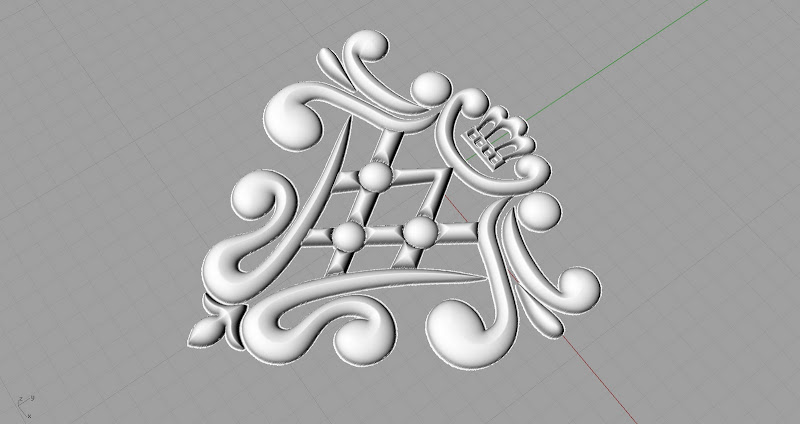

The Dragon itself was modelled by Colin Creed in Sculptris and 3DCoat. the Ring was Matrix3d and the floral inlays where RhinoArt.

Workflow (quoted from http://3dcadjewelry.com/forum)

FYI on workflow for the balance here, had a few queries.

Dragon "decimate"

1: Import OBJ

2: Drape (with a few extra steps to produce a nice drape)

3: Trim

4: Cageedit.

Ring

1: Curves as per picture from photograph.

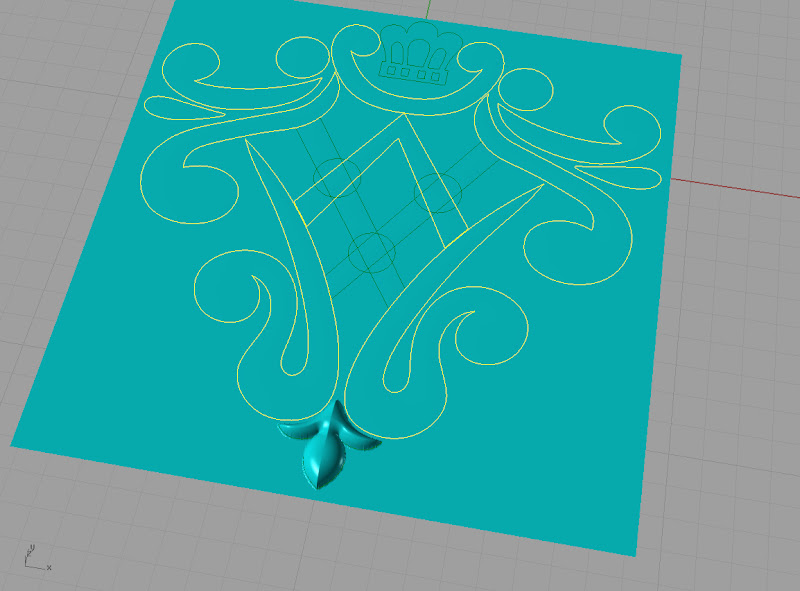

2: Scrolly patterns in RhinoArt

3: Ring in Matrix Signet Builder

4: Insets with Matrix Inset Tool

5: ExtractSrf all insets and CreateUvCrv

6: FlowAlongSrf the RhinoArt meshes.

7: Matrix Milligrain Tool.

8: Place Dragon

By far the drape and cageEdit of the dragon took the longest, the rest of the ring was childs play.

Big thanks to Colin

Owe you a beer.. oh ya and some $$$$

[/quote]

[/quote]