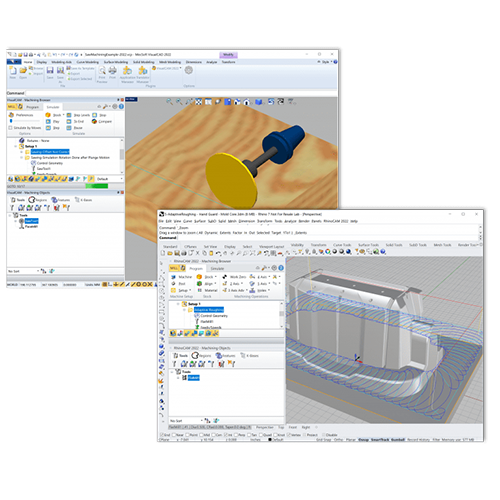

MecSoft Releases CAMJam 2019

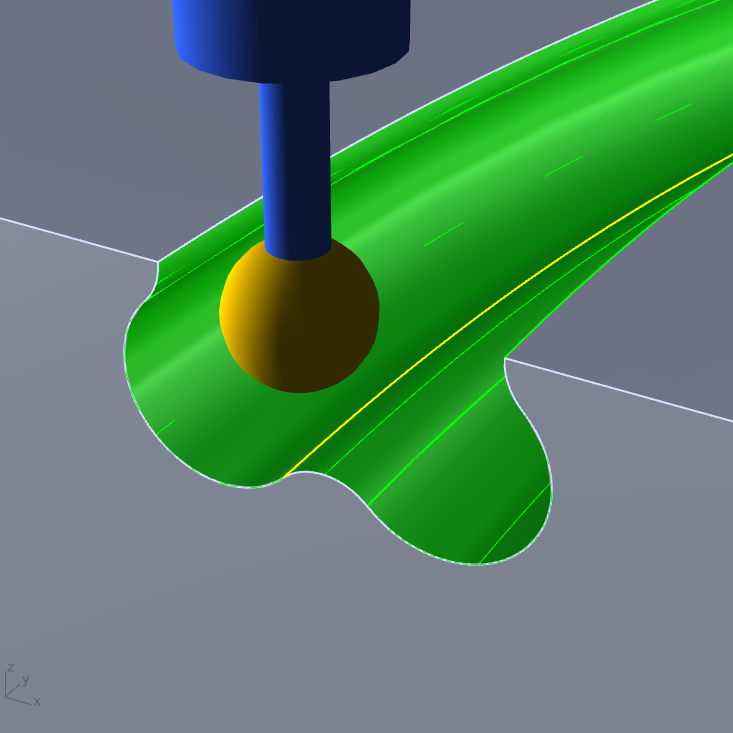

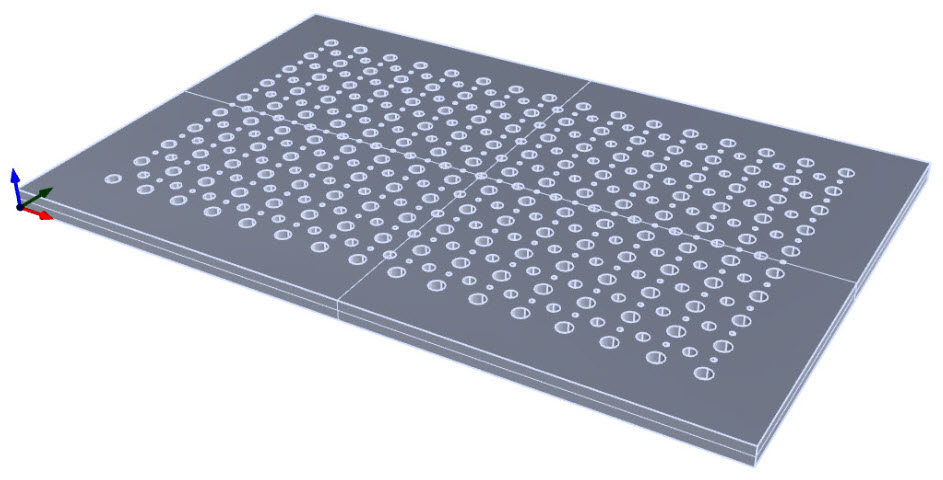

Irvine, CA, April 8, 2019: MecSoft Corporation announces today the release of CAMJam 2019, the Video Training Companion for their popular VisualCAD/CAM®, RhinoCAM®, VisualCAM® for SOLIDWORKS and AlibreCAM® Milling modules. CAMJam 2019 is a video archive and viewing guide of training sessions conducted by the