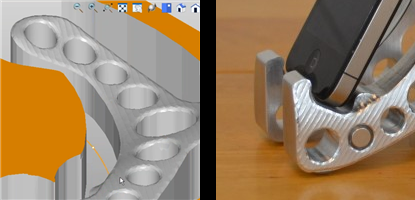

In previous blog posts and case studies, we’ve highlighted how designers are incorporating toolpath cutter step over cusp height as design features. Here is a recap from our KickStarter on product design sent to us from VisualCAM user Shawn White, CEO of TRANSFIXION DESIGN, a product development and manufacturing company located in Matthews, NC.

This part is a sculpted 6061 aluminum stand for iPad®, Galaxy®, Kindle® and iPhone® devices. By design, the 3 Axis Parallel Finishing operation uses a 3/8” ball mill and a 20% step over to achieve the sculpted look and feel that Shawn was looking for.

In previous blog posts and case studies, we’ve highlighted how designers are incorporating toolpath cutter step over cusp height as design features. Here is a recap from our KickStarter on product design sent to us from VisualCAM user Shawn White, CEO of TRANSFIXION DESIGN, a product development and manufacturing company located in Matthews, NC.

This part is a sculpted 6061 aluminum stand for iPad®, Galaxy®, Kindle® and iPhone® devices. By design, the 3 Axis Parallel Finishing operation uses a 3/8” ball mill and a 20% step over to achieve the sculpted look and feel that Shawn was looking for.