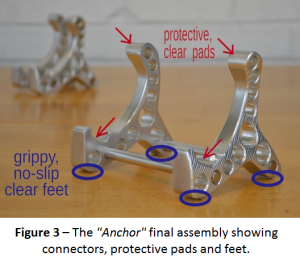

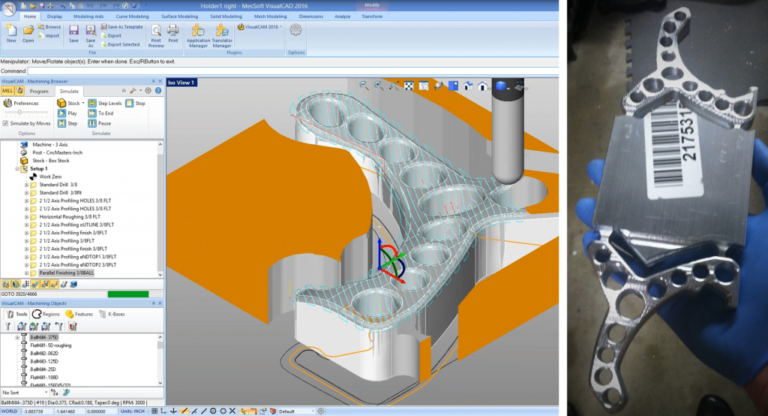

TRANSFIXION DESIGN is a product development and manufacturing company located in Matthews, NC who opened for business in January of 2016. With the help of VisualCAM®, their new product was recently launched on KickStarter.com!

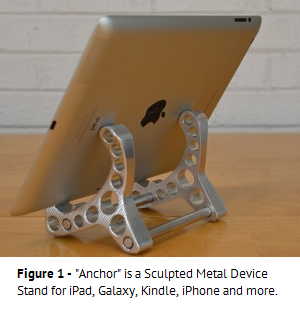

The “Anchor” is a sculpted metal device stand for iPad, Galaxy, Kindle, iPhone and more, manufactured with the help of the VisualCAM® MILL CNC machining software from MecSoft Corporation!

CEO and founder Shawn White sat down with us recently to share some insights into the product and the role that VisualCAM® played in it’s manufacturing.

“When I first got my CNC machine I had zero machining experience and felt a little intimidated! However, after getting started using VisualCAM® I found it was very easy to learn and use. I use it to machine products and prototypes from both wood and metal on our CNCMasters® Barron XL Mill.”

For more information about the “Anchor” sculpted metal device stand from TRANSFIXION DESIGN, feel free to visit their link on KickStarter.com or their website.

For more information about the VisualCAM® 2016 MILL module, including configurations and videos, please visit our software product page.