Did you know that MecSoft’s MILL Module plugins have a built-in Feeds & Speeds Calculator? That’s right, you can ask the program to suggest feeds & speeds values based on your current stock material and active tool parameters! Once a Cut Feed is calculated, you can then choose to automatically assign feed rate values for the various toolpath motions in your operation including Plunge, Approach, Engage, Retract and Departure! The percentages of the Cut Feed to assign are all controlled from the CAM Preferences dialog.The Milling Feeds & Speeds Calculator

Did you know that MecSoft’s MILL Module plugins have a built-in Feeds & Speeds Calculator? That’s right, you can ask the program to suggest feeds & speeds values based on your current stock material and active tool parameters! Once a Cut Feed is calculated, you can then choose to automatically assign feed rate values for the various toolpath motions in your operation including Plunge, Approach, Engage, Retract and Departure! The percentages of the Cut Feed to assign are all controlled from the CAM Preferences dialog.The Milling Feeds & Speeds Calculator

Of course, you can override any of these calculated values at any time, for any tool and for any operation. In Part 1 below we discuss how feeds & speeds are assigned, the basics of the Feeds & Speeds Calculator and how it works. For more advanced users stay tuned for Part 2 where we will discuss how you can customize the Feeds & Speeds Calculator to add additional stock materials.

Feeds & Speeds Associated with a Tool

In the MILL Module, feeds & speeds can be defined and associated with a specific tool. This allows you the flexibility to have different tool definitions based on the type of material being cut (i.e., steel, wood, acrylic, etc.) or the operation type (Pocketing, Facing, etc.). The Create/Select Tool dialog includes a Feeds & Speeds tab where these values are defined. When the tool is saved, the feeds & speeds values are saved with it.

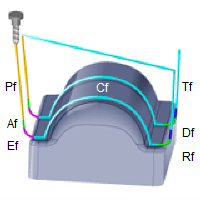

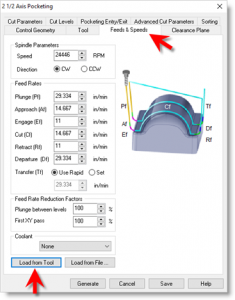

Each toolpath operation type also has a Feeds & Speeds tab in its dialog. This allows you the flexibility to assign feeds & speeds values specific to that operation. The 2½ Axis Pocketing operation dialog is shown here.

Each toolpath operation type also has a Feeds & Speeds tab in its dialog. This allows you the flexibility to assign feeds & speeds values specific to that operation. The 2½ Axis Pocketing operation dialog is shown here.

Each Feeds & Speeds tab also contains a button called Load from Tool. This allows you to load the feeds & speeds values that you have previously associated with active tool. The Active Tool simply refers to the tool that you have selected from the Tools tab of the dialog.

As you can see, just between the tool and the operation type, you have a wide range of flexibility for defining your feeds & speeds strategy.

The Feeds & Speeds Calculator

The Feeds & Speeds Calculator

You may have noticed that both the Feeds & Speeds tab of the Create/Select Tool dialog and the Feeds & Speeds tab of the operation dialog have a button called Load from File. Selecting this button will display the Feeds & Speeds Calculator dialog. This dialog allows you to load feeds & speeds values that are calculated from information stored in an external Materials XML file.

How Does it Work?

There are two parts to the calculator.

Data from Table

This information is extracted from the default Materials XML table file and is based on the following parameters:

- The Stock Material is selected from the Materials dialog located on the Program tab.

- The Tool Material is selected from the Properties tab of the Create/Select Tools dialog.

The values for Surface Speed (measured in units per minute) and Feed per Tooth (measured in units) are retrieved from the XML file and displayed in the dialog. Units refers to the part file’s current Units setting.

Input Variables

The values for Tool Diameter and # of Flutes are automatically loaded based on the tool selected for the operation (i.e., the active tool). Based on these parameters, the program computes a Spindle Speed value measured in RPM (Rotations per Minute).

Computed Cut Feedrate

A Cut Feed value is also calculated for you (measured in Units/Minute) based on Stock Material, Tool Material, Tool Diameter, and # of Flutes. Changing the Spindle Speed updates the Cut Feed and vice versa.

When you pick OK from this dialog, the computed Feeds & Speeds values are submitted to either the active tool or the active toolpath operation.

Formulas Used for Cut Feed Computation

| Units in Inches | |

| Spindle Speed (RPM) | Surface Speed (SFM) x 12 / ( x Tool Diameter(in)) |

| Cut Feed (IPM) | Feed Per Tooth(IPT) x # of Flutes x Spindle Speed(RPM) |

| SFM: Surface Feet Per Minute IPT: Inches Per Tooth RPM: Revolutions per Minute IPM: Inches Per Minute |

|

| Units in Millimeters | |

| Spindle Speed (RPM) | Surface Speed (SMM) * 1000 / ( x Tool Diameter (mm)) |

| Cut Feed (MMPM) | Feed Per Tooth(MMPT) x # of Flutes x Spindle Speed(RPM) |

| SMM: Surface Meters Per Minute MMPT: Millimeters Per Tooth RPM: Revolutions per Minute MMPM: Millimeters Per Minute |

|

Let’s Review:

- You can associate unique feeds & speeds values with each tool or with each operation.

- You can invoke the Feeds & Speeds Calculator from either the Create/Select Tool dialog or from any toolpath operation dialog.

- The Feeds & Speeds Calculator extracts data from an external XML file and combines it with your stock material and tool parameters to calculate suggested Spindle Speed and Cut Feed

- Changing parameters such as Tool Diameter, Surface Speed, Material, etc. will calculate new Spindle Speed and Cut Feed values automatically.

- A percentage of the calculated Cut Feed can be assigned for Plunge, Approach, Engage, Retract and Departure

- You can override ANY or ALL of the suggested feeds & speeds values at any time!

See Also:

Feed Rates Explained – Extend the Life of Your CNC Tools and Machines