Carl and Gina Hill operate their cottage business Quail Pens from their home in Wallace Idaho. Referred to as the Silver Capital of the World, Wallace is an historic city in the Panhandle Region of northern Idaho. Wallace is the county seat of Shoshone County and has three active silver mines plus one semi-active gold mine!

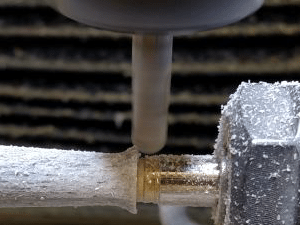

Carl uses RhinoCAM Expert to machine the outer base and cap of his signature line of Quail Pens on his 4 Axis CNC machining center. In the example shown here, Carl is cutting the outer base of their Antler Pen product. That’s right, the stock material is elk and some deer antler! Because of the porous nature of the material, a brass sleeve is glued into a drilled hole through its center. The antler is also soaked with a stabilizing agent that allows it to be machined to size. All of the antlers that Carl uses are shed which means they are picked up off the ground after the buck sheds them in the spring. No animals are harmed in the production of Carl’s products!

In the image shown below we see the 3D surface model of the Antler Pen base in Rhino 5.0. You can clearly see the brass sleeve located at its center. In the Machining Job tree on the left we see two Work Zeros, one for the Cap and one for the Base. The first operation for the base is 4 Axis Engraving. Carl uses this to machine a 15 degree conical on the flared end of the base. Then we see two 4 Axis Parallel Finishing operations. The first is, for roughing uses a ¼” dia. Ball Mill, 8% (0.020”) step over and 35% step down (0.087”) that leaves 0.015” of stock. The second one is the finishing operation using a 0.047” dia. Ball Mill, 2.5% (0.006”) step over.

Carl and Gina Hill operate their cottage business Quail Pens from their home in Wallace Idaho. Referred to as the Silver Capital of the World, Wallace is an historic city in the Panhandle Region of northern Idaho. Wallace is the county seat of Shoshone County and has three active silver mines plus one semi-active gold mine!

Carl uses RhinoCAM Expert to machine the outer base and cap of his signature line of Quail Pens on his 4 Axis CNC machining center. In the example shown here, Carl is cutting the outer base of their Antler Pen product. That’s right, the stock material is elk and some deer antler! Because of the porous nature of the material, a brass sleeve is glued into a drilled hole through its center. The antler is also soaked with a stabilizing agent that allows it to be machined to size. All of the antlers that Carl uses are shed which means they are picked up off the ground after the buck sheds them in the spring. No animals are harmed in the production of Carl’s products!

In the image shown below we see the 3D surface model of the Antler Pen base in Rhino 5.0. You can clearly see the brass sleeve located at its center. In the Machining Job tree on the left we see two Work Zeros, one for the Cap and one for the Base. The first operation for the base is 4 Axis Engraving. Carl uses this to machine a 15 degree conical on the flared end of the base. Then we see two 4 Axis Parallel Finishing operations. The first is, for roughing uses a ¼” dia. Ball Mill, 8% (0.020”) step over and 35% step down (0.087”) that leaves 0.015” of stock. The second one is the finishing operation using a 0.047” dia. Ball Mill, 2.5% (0.006”) step over.

|  |  |  |

The Antler Pen is unique, literally! No two pens are the same and each bears the rustic look of the great outdoors!

For more Information:

- For more information about Carl & Jina Hill at Quail Pens, we invite you to visit them on the web at http://www.quail-pens.com/.

- For more information about RhinoCAM Expert, please see our RhinoCAM Product Page.