Tamas Fay of T-FAY TECH uses RhinoCAM 2016 MILL Professional configuration in his machine shop every day and boasts that he has no trouble achieving the high level of accuracy required by his Tool & Die component applications. Materials typically used include aluminum, plastics (derlin and semitron), steel, tool steel (A2, 4140, D2) ans stainless.

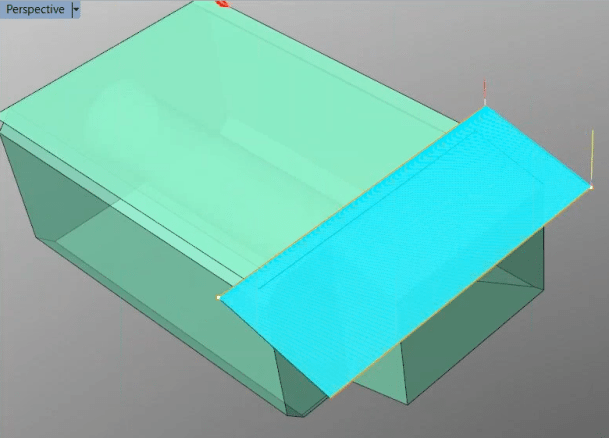

For cutting precise angles on part features from Tool Steel – where others might use grinding techniques, I have no problem using a parallel finishing toolpath strategy. Using a ¼” ball mill and a very fine 0.003” stepover – then a once-over with a fine honing stone and that’s it!