I’m very excited to write about our new 2018 line-up of MecSoft CAM plugins. This release is packed full of new features and exciting enhancements! In this post we will explore what’s new in Automatic Feature Machining in 2018. Click here to learn more about our 2018 Milling products.

I’m very excited to write about our new 2018 line-up of MecSoft CAM plugins. This release is packed full of new features and exciting enhancements! In this post we will explore what’s new in Automatic Feature Machining in 2018. Click here to learn more about our 2018 Milling products.

Even more Automation!

![]() MecSoft CAM in 2018 goes even further than our previous release with additional automation tools for detecting and machining 3D part features! We have introduced Automatic Feature Detection (AFD) and Automatic Feature Machining (AFM) in addition to many new commands on the Features tab toolbar. The (AFD) command automatically detects features on the entire part model! You can still perform Interactive Feature Detection (IFD) from a single selected orientation like in previous versions. The new (AFD) command analyzes the part from all directions and lists each machining orientation along with its detected features.

MecSoft CAM in 2018 goes even further than our previous release with additional automation tools for detecting and machining 3D part features! We have introduced Automatic Feature Detection (AFD) and Automatic Feature Machining (AFM) in addition to many new commands on the Features tab toolbar. The (AFD) command automatically detects features on the entire part model! You can still perform Interactive Feature Detection (IFD) from a single selected orientation like in previous versions. The new (AFD) command analyzes the part from all directions and lists each machining orientation along with its detected features.

After detecting your machinable part features, you can take advantage of our new Automatic Feature Machining (AFM) to program your toolpaths automatically! (AFM) works in conjunction with a knowledge base of toolpaths assigned to specific feature types that are detected in your part model. The program is installed with a free AFM Knowledge Base that you can use and customize for your specific part features!

Feature Machining Rules & Knowledge Bases

![]() If you’re currently taking advantage of our Knowledge Base tools to automate your machine programming, you will like this enhancement. Now you can perform Automatic Feature Machining (AFM) by assigning Feature Machining Rules to your Knowledge Bases! This is in addition to the geometry-based rules available in previous versions! Machine programming families-of-parts with similar features is now completely automated with (AFM). Just add rules to your knowledge base, open a similar family part, load your knowledge base and regenerate. How simple is that!

If you’re currently taking advantage of our Knowledge Base tools to automate your machine programming, you will like this enhancement. Now you can perform Automatic Feature Machining (AFM) by assigning Feature Machining Rules to your Knowledge Bases! This is in addition to the geometry-based rules available in previous versions! Machine programming families-of-parts with similar features is now completely automated with (AFM). Just add rules to your knowledge base, open a similar family part, load your knowledge base and regenerate. How simple is that!

Even more Features Detected!

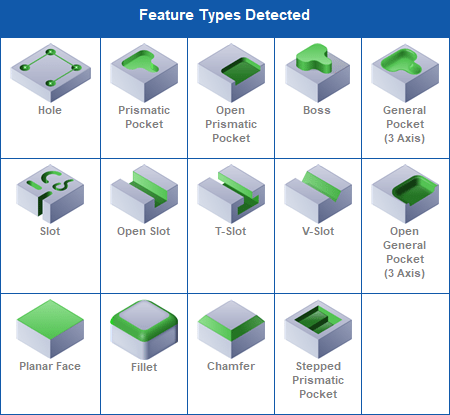

In this release we’ve added even more features that can be automatically detected such as Fillets and Stepped Pockets. Here is the complete list of features that you can detect automatically in 2018:

Feature Information Reporting

![]() If you have families-of-parts with lots of features you will like our new Feature Information Report. This instantly provides the information you need to analyze and act on programming your feature-based toolpaths. Each machining Orientation is listed in the report along with the Feature Type, Feature Name and critical Feature Parameters.

If you have families-of-parts with lots of features you will like our new Feature Information Report. This instantly provides the information you need to analyze and act on programming your feature-based toolpaths. Each machining Orientation is listed in the report along with the Feature Type, Feature Name and critical Feature Parameters.

Enhanced Feature Interaction

With more Feature Detection you need more interaction tools right? Well we’ve got you covered with an even better User Interface that allows you to work smarter and faster on feature-rich parts. You get immediate visual feedback on detected features both on the 3D part and in the Features list. Dynamic tooltips provide critical feature information. Smart, right-click feature menus populate with only the toolpath options that apply to that feature type. No mess and no mistakes!

Interactive Feature Machining (IFM)

Now you can interact with detected features to perform machining operations and other Feature Machining tasks. Just right-click on a detected feature either from the Features tree or from the part model and select from a menu of supported operations. This makes Interactive Feature Machining (IFM) intuitive and fast.

To Learn More about Feature Machining in MecSoft’s CAM Milling Plugins

1. To learn more about what you can do with Feature Machining, visit the online help supplied with your program.![]()

2. Also, take a moment to watch the following free video tutorials:

What’s New in 2018 Webinar Replay What’s New in 2018 Webinar Replay |  RhinoCAM 2018 Automatic Feature RhinoCAM 2018 Automatic FeatureMachining (AFM) Quick Start |