In the first segment of this post [link to first post] we showed you how Keith Dube of Dubes Custom Street Machines (Hudson, NH) uses VisualCAD/CAM’s TURN module (VisualTURN) to program the toolpaths needed to machine the front and back of the center caps for the wheels on the 811 Car, a 2016 Callaway SC757 Corvette Z06 promotion by 1-Call Concepts and customized by Paul Jr. Designs. In the second segment, we showed you how Keith used VisualCAM’s MILL module (VisualMILL) to complete the center cap machining job.

In this final segment, we see how Keith machines a custom tool to mount/unmount the center caps in addition to thread milling the hubs of the wheel blanks to mount the center caps. Let’s have a look.

Multiple Setups for Indexed (Flipped) Machining

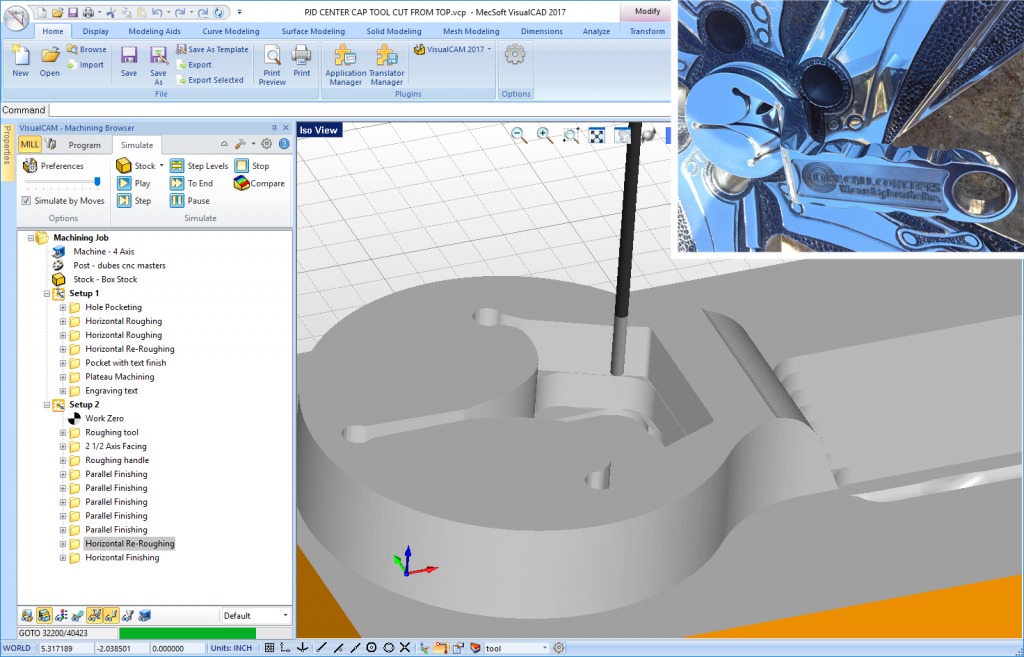

The unique design of this tool requires milling from two sides. Notice Setup 1 and Setup 2 in the Machining Job tree on the left side in the image below. The Professional configuration of VisualMILL allows for unlimited setups within the same part file in addition to a suite of Advanced 3 Axis toolpath strategies.

In Setup 1 you see 3 Axis Horizontal Roughing, Re-Roughing and Plateau Machining in addition to 2½ Axis Pocketing, Hole Pocketing and Engraving. In Setup 2 you see 3 Axis Horizontal Roughing, Re-Roughing, Horizontal Finishing and Parallel Finishing in addition to 2½ Axis Facing. The completed tool is pictured (inset) after sanding and polishing.

Thread Milling the Wheels

To mount the center caps on the wheels, Keith used 2½ Axis Profiling and then Thread Milling to machine the access diameter and threads. For Thread Milling you can use a single or multi point thread tool. The Create/Select Tool dialog for Thread Milling tools is shown below.

Here we see how Keith uses multiple 2½ Axis Profiling operations to prep the hub of the wheels for threading. These are listed in the Machining Job tree as O-RING EDGE, RECESS CAP and THREADING OD. Following these, the Thread Milling operation is performed. The operation dialog for Thread Milling is shown in the image below. Notice that the entire wheel geometry does not need to be defined. Being a 2½ Axis toolpath, simple 2D curves can be used.

Additional Images

For more information

VisualCAD/CAM, VisualTURN and VisualMILL product and download information and links go here.

Reference Links:

Keith Dube and the awesome projects at Dubes Custom Street Machines

The 811 Car from 1-Call Concepts

The awesome projects from Paul Jr. Designs

The 2016 Callaway SC757 Corvette Z06