ENVIBOATS located in Jacksonville, North Carolina is a quality supplier of semi-custom boat jigs developed in the Carolina style. Their jigs are produced from full 3D computer-aided designs and are completely CNC cut to ensure that both the professional boatbuilder as well as the DIY’er can build a sound, high-quality boat in the shortest time possible. To speed up the process even more, they offer many boat components pre-cut. They are placed into the jig and the hull is molded with them in place to save time.

Marc Shlaes, owner/operator of ENVIBOATS had a long career in Information Technology before launching ENVIBOATS. Marc has enjoyed boat design and boat building his whole life and has always been a boater.

ENVIBOATS located in Jacksonville, North Carolina is a quality supplier of semi-custom boat jigs developed in the Carolina style. Their jigs are produced from full 3D computer-aided designs and are completely CNC cut to ensure that both the professional boatbuilder as well as the DIY’er can build a sound, high-quality boat in the shortest time possible. To speed up the process even more, they offer many boat components pre-cut. They are placed into the jig and the hull is molded with them in place to save time.

Marc Shlaes, owner/operator of ENVIBOATS had a long career in Information Technology before launching ENVIBOATS. Marc has enjoyed boat design and boat building his whole life and has always been a boater.  |

|

|

|

Marc started out using a competitor’s CAM software but when it came to technical support and wanting to suggest enhancements, the company was not at all helpful. That’s when Marc turned to MecSoft and RhinoCAM. His first project was hatch lids and gutter systems that he was supposed to deliver yesterday! Marc turned to MecSoft support and got the job done quickly. We recently sat down with Marc to discuss his unique business and how RhinoCAM has helped him succeed.

|

“Initially we were using a different CAM system for our 2-1/2 Axis toolpaths. Then when it came time to cut in 3 Axis, that system and their technical support was not up to the task. That was the day we purchased RhinoCAM. MecSoft Corporation provides the same quality technical support that I provide my customers and I like that!” Marc Shlaes, Owner/Operator ENVIBOATS, Jacksonville, North Carolina |

Hull Jigs & Fixtures (2½ Axis Machining)

ENVIBOATS utilizes RhinoCAM’s 2½ Axis machining strategies to design and manufacture all of the jigs and fixtures that go into their DIY boat building kits. The series of images shown below illustrate the process of using an ENVIBOAT kit to build your very own lightweight, strong and seaworthy boat. In Rhino, the complete boat is designed both internally and externally along with the complete jig framing and other structures needed during construction. This is shown in image (A). The components are then nested onto 4”x8” marine plywood sheets where they are cut using 2½ Axis Profiling toolpaths. RhinoCAM’s automatic Bridges & Tabs in Profiling are utilized to keep the machined components within the plywood sheets. A typical sheet is shown in image (B).

|

|

The kit is then shipped to the customer along with all the accessories they need to complete the build. In image (C) below we see the jig structure assembled on-site. It is used to cold-mold the hull of the boat. It is referred to as cold-mold because the glues used during construction cure under normal room temperature. The kit also includes many CNC-machined internal structural components ENVIBOATS calls “FasBild™ Options”. The ability for RhinoCAM to accurately machine these components saves the builder countless hours.

In image (D) you see the monocoque triple laminate core planking after it is installed onto the hull jig. Monocoque is a common term in engineering that, translated literally, means “single shell”. Monocoque structures used typically in boats, aircraft, and high-performance automobiles derive most of their strength from the “shell”

|

|

After the wooden hull core is prepped and layered with its external fiberglass hull, it along with the entire jig structure is turned right-side up. The jig structure is then removed and discarded, leaving the stringers and any other internal hull structures intact. At this point the remaining monocoque triple-laminate core planking is sheathed in epoxy/fiberglass, both inside and out, primarily for abrasion resistance and encapsulation. After this stage, the hull is complete and you are ready to assemble the bridge, console and/or cabin and accessories. The completed boat is shown in image (F) below on its maiden voyage!

|

|

Bridge & Console Accessories (2½ Axis Machining)

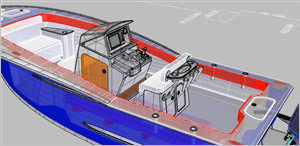

ENVIBOATS also utilizes RhinoCAM’s 2½ Axis machining strategies to design and manufacture the bridge and console accessories for their custom boat kits. In images (A) and (B) below we see the 3D rendering of the boat along with the jig framing and windshield being assembled. In images (C) and (D) we see a typical driver’s console. For all interior accessories RhinoCAM toolpaths are used to fabricate the required interior jigs and forms as well as any positive molds required for fiberglass layup. In images (A) and (B) below we see the 3D rendered boat in Rhino and the actual jig frame with the windscreen assembled over it. Images (C) and (D) show a typical driver’s console.

|

|

|

|

Three-Step Keyed Scarf (2½ Axis Machining)

For structural components such as stringers and bulkheads that must be glued up, ENVIBOATS utilizes their own joint developed through countless hours of design and testing. This accurately-machined joint enables builders to assemble these components in a fraction of the time previously required. The Three-Step Keyed Scarf (shown here) is created from RhinoCAM 2½ Axis toolpaths. Each component section interlocks during assembly

Hatches & Interior Cabin Accessories (3 Axis Machining)

ENVIBOATS utilizes RhinoCAM’s 3 Axis machining strategies to design and manufacture the deck hatches, gutter framing as well as interior cabin accessories. For hatch lids and hatch gutter framing, positive form molds are machined from RhinoCAM toolpaths. The forms are then used to layup the actual fiberglass components. In many cases RhinoCAM is used to machine the actual component accessory such as the interior framing shown in the images below.

|

|

|

|

More about ENVIBOATS

ENVIBOATS, located in Jacksonville, North Carolina is a quality supplier of semi-custom boat jigs developed in the Carolina style. Their jigs are produced from full 3D computer-aided designs and are completely CNC cut to ensure that both the professional boatbuilder as well as the DIY’er can build a sound, high-quality boat in the shortest time possible. To learn more about ENVIBOATS we invite you to visit their website and Facebook page.

More about RhinoCAM

RhinoCAM – MILL is available in five different configurations (Express, Standard, Expert, Professional and Premium). The part shown here was programmed using the Standard configuration. Here are some additional details about each of the available configurations. For the complete features list, visit the RhinoCAM Product Page.

- RhinoCAM MILL Express: This is a general-purpose program tailored for hobbyists, makers and students. Ideal for getting started with CAM programming. Includes 2 & 3 axis machining methods. Includes ART & NEST modules as well!

- RhinoCAM MILL Standard: This configuration includes everything that is in the Express configuration and additional 2-1/2 Axis, 3 Axis & Drilling machining methods. Also now includes 2½ Axis Turning!

- RhinoCAM MILL Expert: Suitable for 4 Axis rotary machining. Includes the Standard configuration, plus 4 Axis machining strategies, advanced cut material simulation and tool holder collision detection.

- RhinoCAM MILL Professional: Ideal for complex 3D machining. Includes the Standard and Expert configuration, plus advanced 3 Axis machining strategies, 5 Axis indexed machining, machine tool simulation, graphical toolpath editing and a host of other features.

- RhinoCAM MILL Premium: Tailored for complex 3D machining with both 3 Axis and full 5 Axis methods. Includes the Standard, Expert and Professional configurations, plus 5 Axis simultaneous machining strategies.

For the complete features list, we invite you to visit the RhinoCAM Product Page:

Powerful production CAM for Rhino users!