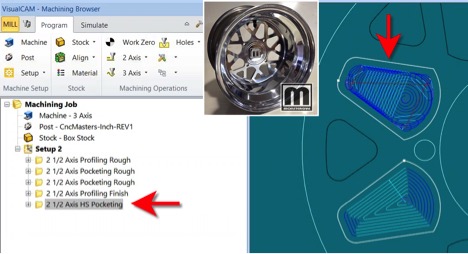

Steve Gold owner/proprietor of MonsterGy6 Customs in Alpharetta GA, experiments with 2½ Axis High Speed Pocketing using VisualMILL® 2016. High Speed Pocketing produces a cut pattern that reduces tool pressure and keeps chip load more consistent and generally results in faster cycle times (i.e., higher cut feed rates can be used) and longer tool life, when compared to traditional pocketing cut patterns. The cut pattern is characterized by progressive arc-shaped passes that nibble away at the stock material.

In this Indy wheel design from MonsterGy6 Customs, 2½ Axis High Speed (HS) Pocketing is shown alongside a traditional pocketing operation in VisualMILL® 2016. Notice that in the High Speed (HS) cut pattern, the tool engages and begins cutting with a spiral motion and then tangential arcs are added where the tool changes direction. The final chrome-plated wheel is shown in set.