Cutting Edge Technology

A Passion fr DIY

Craig Bernstein of East Massapequa New York is a passionate DIY user who designs and manufacturers his own line of utility knives that he sells locally to friends and co-workers.

I’ve been carrying around pocket knives since I was a young boy and there’s nothing cooler than taking out a pocket knife and when somebody likes it, telling them “I made it myself!”

There’s actually a lot that goes into designing and building your own pocket knife. Craig started out creating them by hand but soon realized he could save considerable amounts of time by using a CNC mill and the right CAD/CAM software.

Craig always liked working with his hands and also liked machining so he took the plunge and purchased a Tormach CNC mill. It came with the Mach3 controller software but Craig soon updated to the Path Pilot controller and RhinoCAM supports both!

Now I don’t know which I like more, using RhinoCAM or making knives!

The Art of the Blade

During the day Craig installs architectural woodwork but soon plans to retire and start making knives full-time using RhinoCAM and his Tormach CNC mill! When asked about learning to use RhinoCAM, Craig says:

I was computer illiterate but once I got started, I was able to program my parts and get where I needed to be relatively easily. With great support from MecSoft I was able to figure it out and get it done!

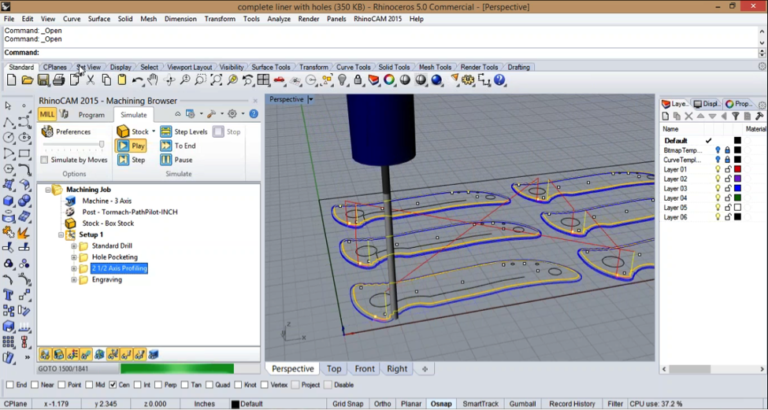

This image shows RhinoCAM 2015 simulating the 2½ Axis Profiling operations used to cut the 0.065” thick Titanium “Liner” of the blade design using a Carbide end mill. This component (one left-hand and one right-hand) can be considered the internal frame that accepts all of the threaded screws, supports the bearing and blade, and also integrates the locking mechanism. The setup shown here also includes Drilling, Hole Pocketing and Engraving operations.

This image shows a few of Craig’s prototype knives, before, during and after the blades have been finished.

For More Information:

MecSoft’s CAD/CAM software solutions are designed to be easy to use and scalable for small-to-medium sized businesses. At the same time, it’s a powerful solution that can effectively integrate with many milling systems. For more information about RhinoCAM® and other CAD, CAM and 3DPRINT solutions that we offer, you can visit us at www.mecsoft.com.