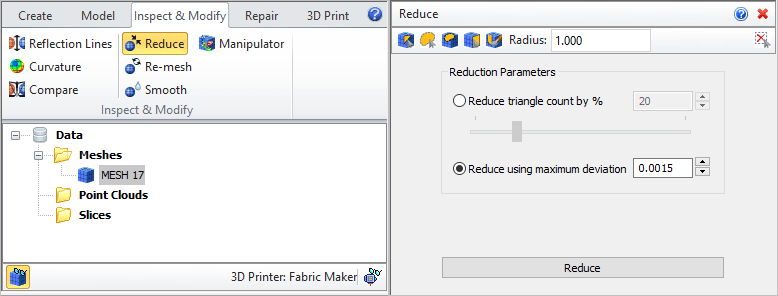

This article describes the use of two different modules in RhinoCAM, RhinoCAM-MESH and RhinoCAM-MILL. The RhinoCAM-MESH module contains an Inspect & Modify menu (shown below) with commands that allow you to Inspect your mesh models using various reflection and curvature comparison techniques. More importantly, the menu contains Mesh modification commands such as Reduce Mesh, Re-Mesh and Smooth Mesh. The Reduce Mesh command is very useful when working with models from programs like ZBrush that produce millions of facet triangles during the course of the sculpting design process.

Using the Reduce by maximum deviation option provides better results than mesh decimation tools in either ZBrush or Rhino, says Jim Lohmann, Owner/Operator of Lohmann Woodcarving Company, in Covington, MI.

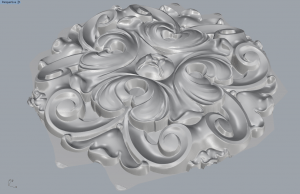

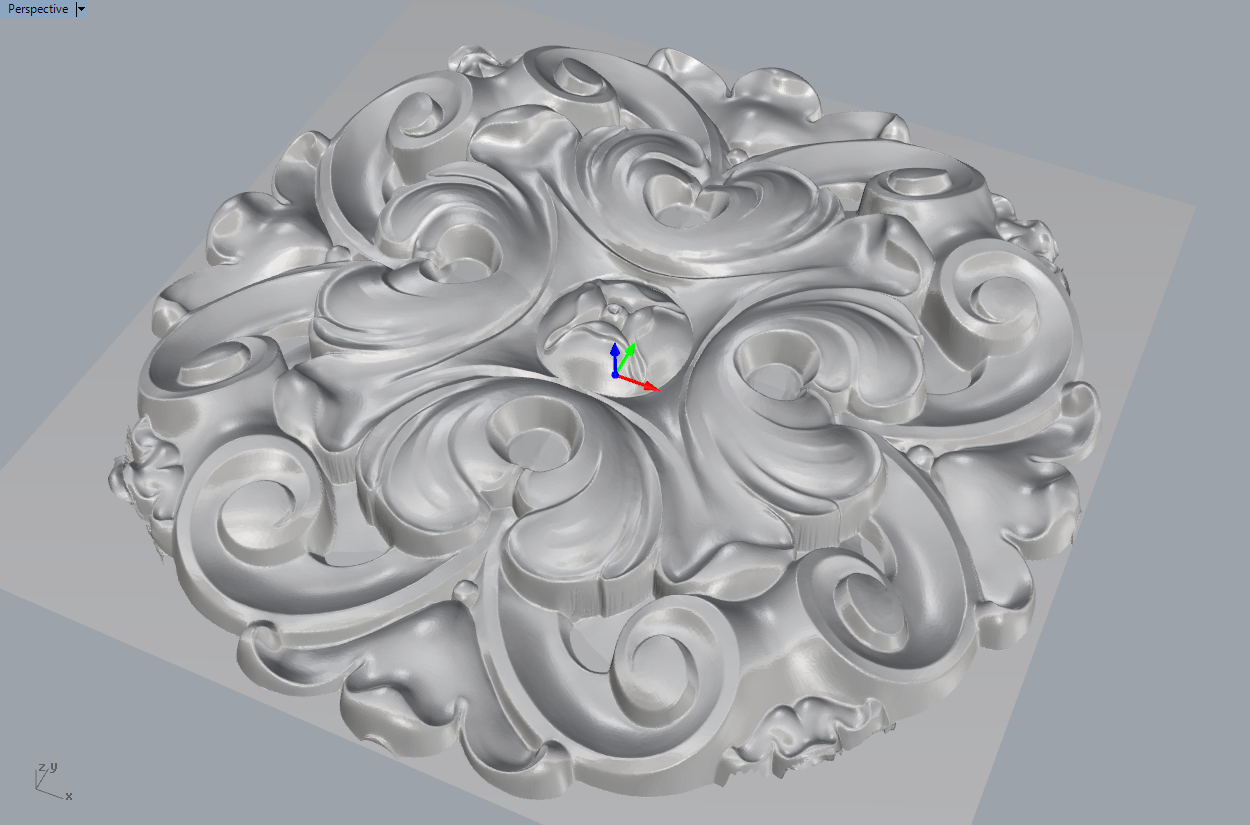

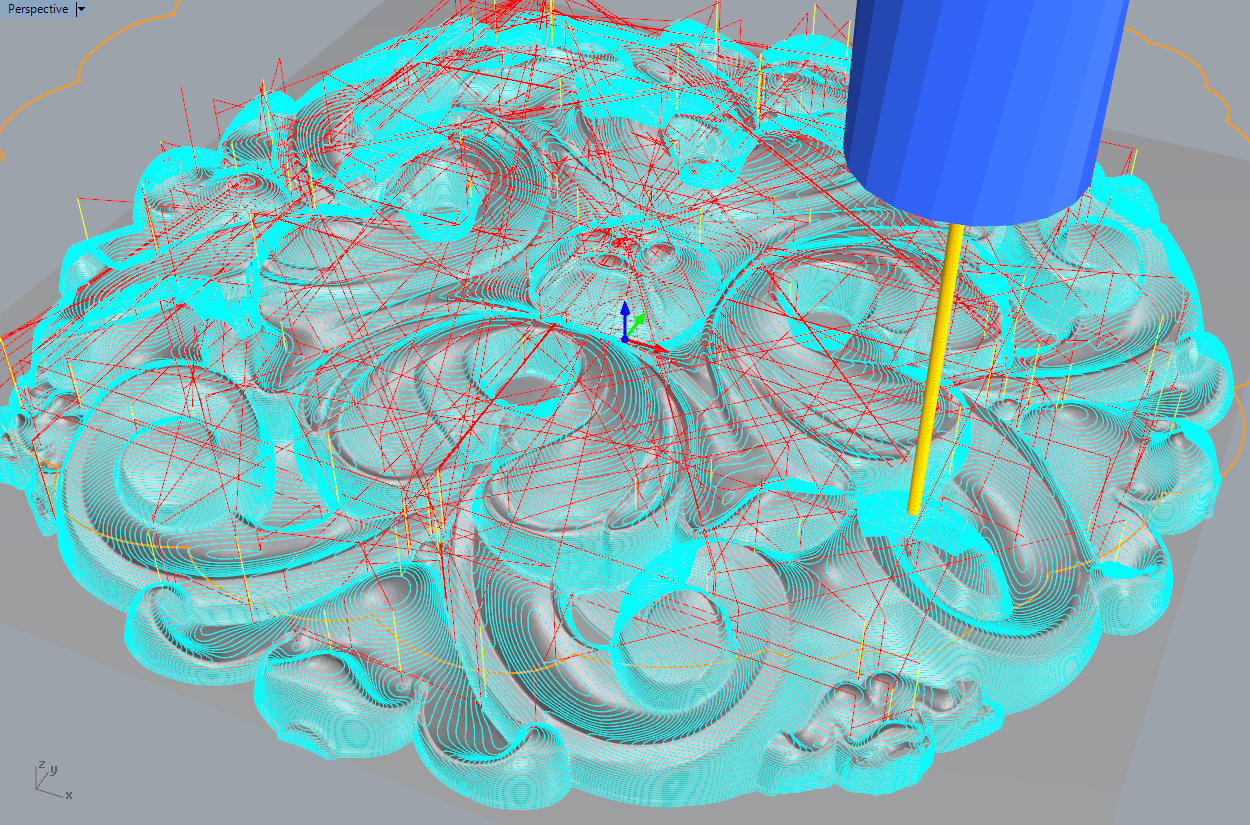

The 6”x6” rosette sample shown below was designed in ZBrush and totaled over 1.87 Million facet triangles when it was opened in Rhino. The RhinoCAM-MESH module removed over 1.3 Million face triangles from the original mesh model. The accuracy of the original model was also maintained to within a maximum deviation of 0.0015”. Jim was better able to manage the reduced mesh that RhinoCAM-MESH produced without sacrificing quality or precision. Have a look at the images in the table below. The actual rosette, machined from mahogany, is shown in the image above.

This article describes the use of two different modules in RhinoCAM, RhinoCAM-MESH and RhinoCAM-MILL. The RhinoCAM-MESH module contains an Inspect & Modify menu (shown below) with commands that allow you to Inspect your mesh models using various reflection and curvature comparison techniques. More importantly, the menu contains Mesh modification commands such as Reduce Mesh, Re-Mesh and Smooth Mesh. The Reduce Mesh command is very useful when working with models from programs like ZBrush that produce millions of facet triangles during the course of the sculpting design process.

Using the Reduce by maximum deviation option provides better results than mesh decimation tools in either ZBrush or Rhino, says Jim Lohmann, Owner/Operator of Lohmann Woodcarving Company, in Covington, MI.

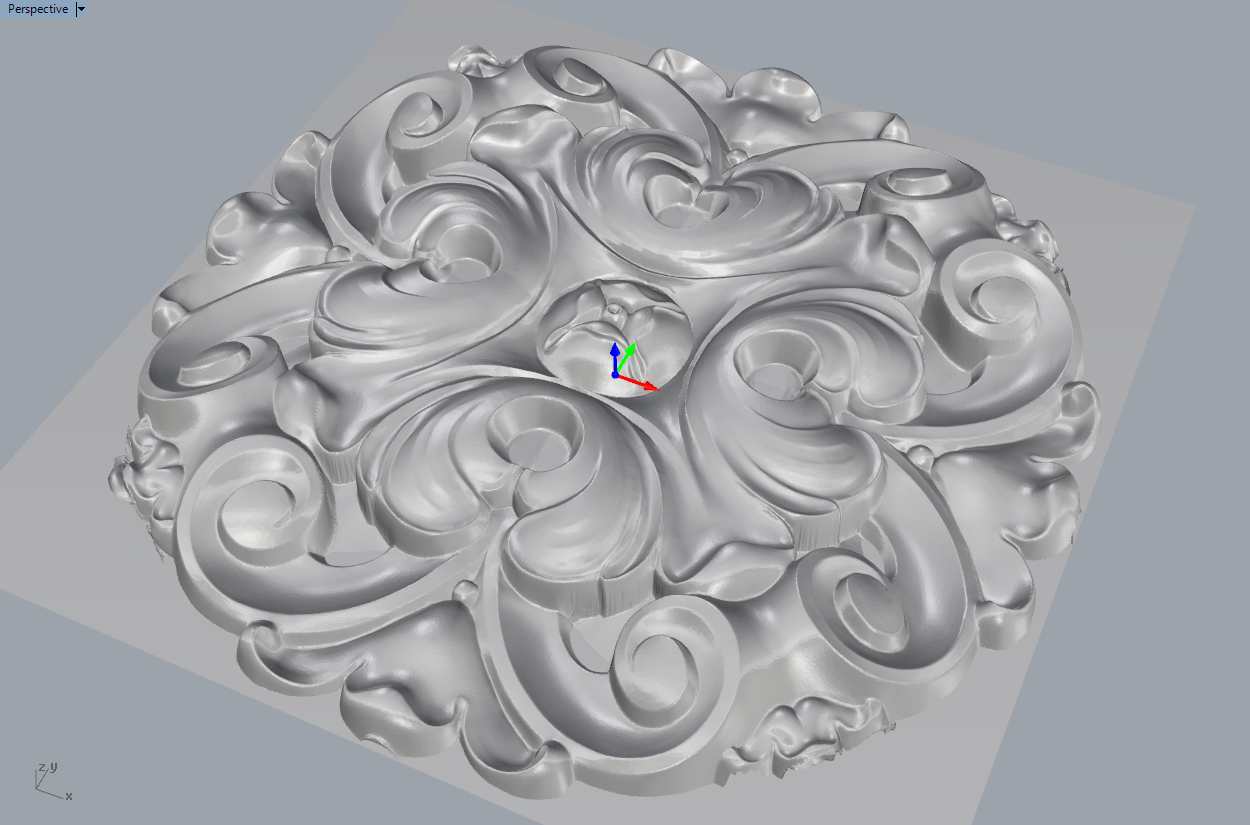

The 6”x6” rosette sample shown below was designed in ZBrush and totaled over 1.87 Million facet triangles when it was opened in Rhino. The RhinoCAM-MESH module removed over 1.3 Million face triangles from the original mesh model. The accuracy of the original model was also maintained to within a maximum deviation of 0.0015”. Jim was better able to manage the reduced mesh that RhinoCAM-MESH produced without sacrificing quality or precision. Have a look at the images in the table below. The actual rosette, machined from mahogany, is shown in the image above.

|

|

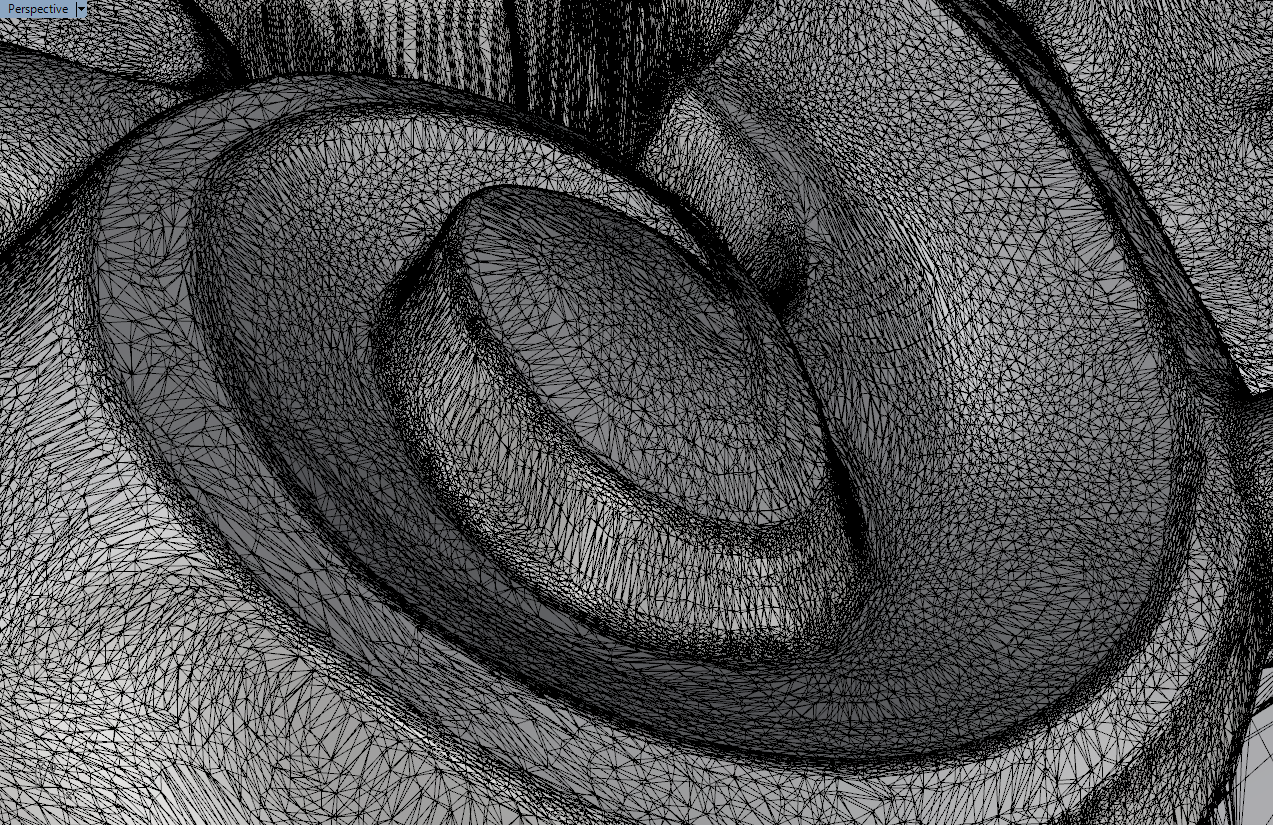

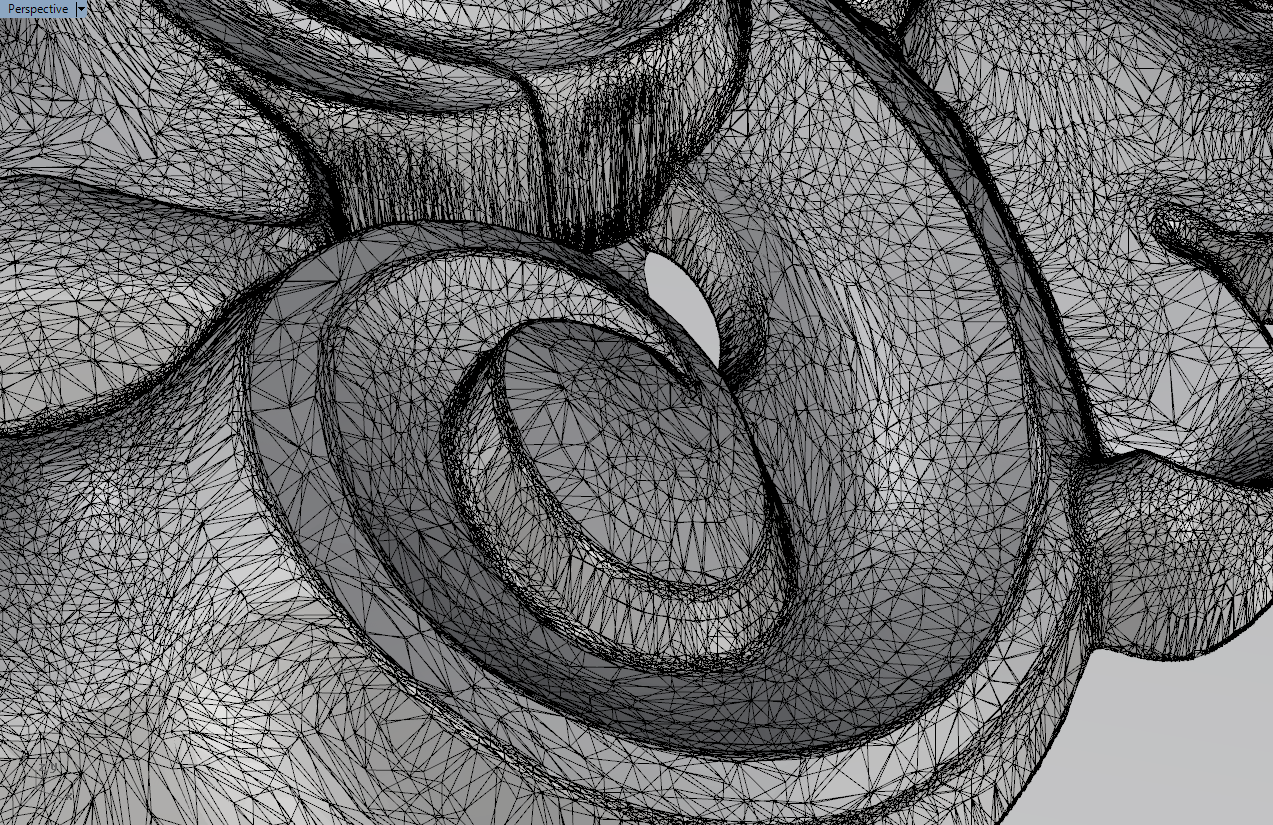

| Original 6”x6” Mesh from ZBrush opened in Rhino contains 1.87 Million Facet Triangles. | |

|

|

| The mesh was reduced by 70% to 0.57 Million Facets using RhinoCAM-MESH with a mix deviation of 0.0015”. | |

Benefits of RhinoCAM-MESH

The following benefits were realized during this project by utilizing the RhinoCAM-MESH module:

- Greater Performance Saves Time: Mesh models ARE resource intensive for downstream applications that work with mesh data. The Reduce Mesh by Max Deviation command removed 70% of the original mesh’s density, allowing the part to be more easily manipulated and processed by both Rhino and RhinoCAM.

- Achieves a High Degree of Accuracy: The Reduce Mesh by Maximum Deviation command allows you to define the amount of deviation that is acceptable for your part and your machining process. In this case, a maximum deviation range of 0.0015” was used.

The RhinoCAM-MILL Toolpath Strategy

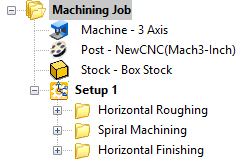

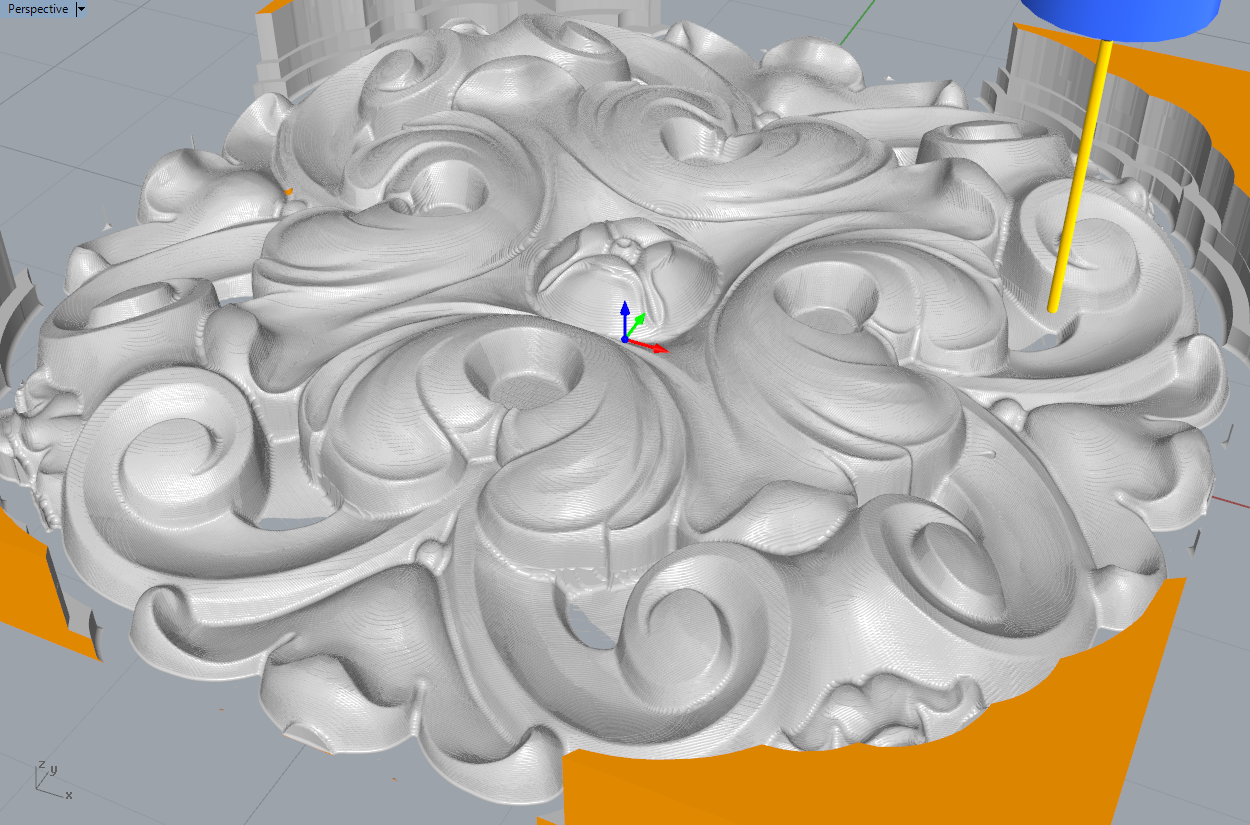

The 6” rosette mesh model was machined using the following toolpath strategies found in the RhinoCAM-MILL module. The Machining Job tree is shown here on the right. Each toolpath strategy is also shown in the images below:

The 6” rosette mesh model was machined using the following toolpath strategies found in the RhinoCAM-MILL module. The Machining Job tree is shown here on the right. Each toolpath strategy is also shown in the images below:

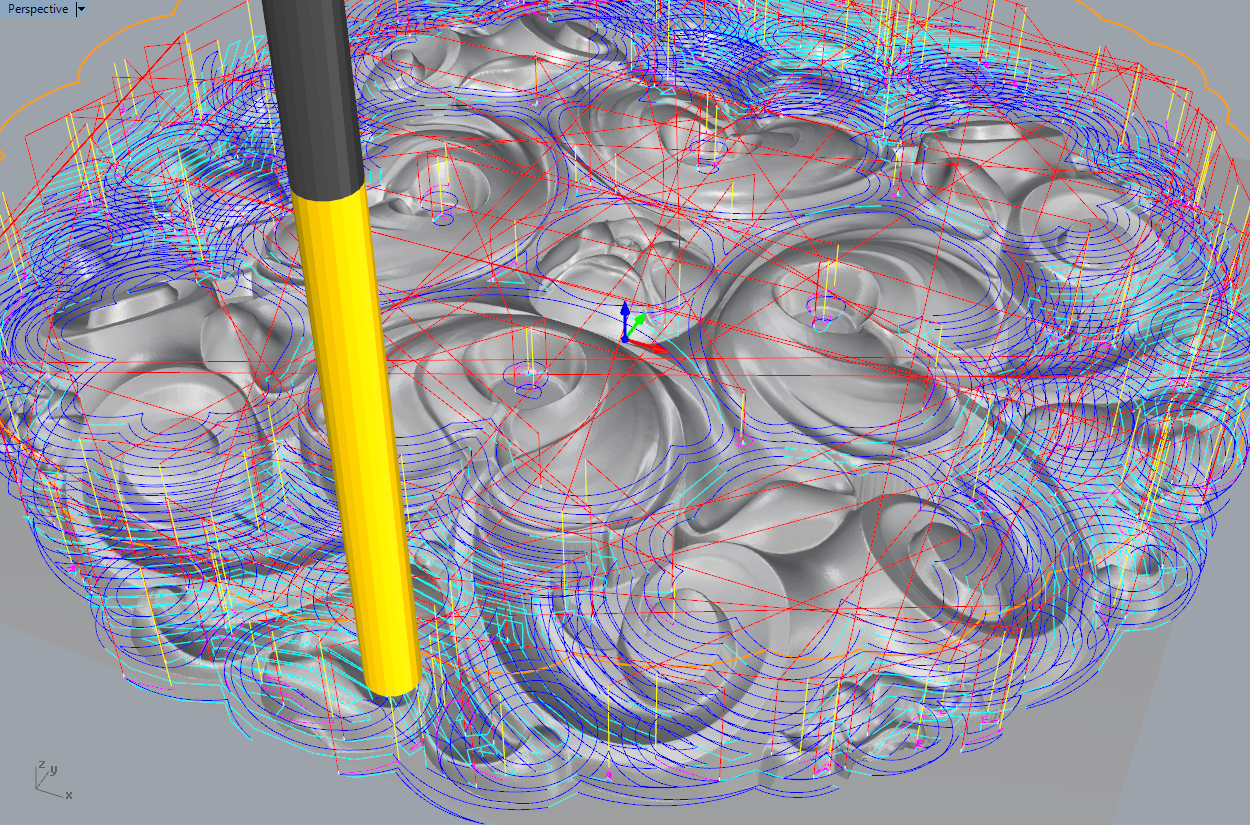

- 3 Axis Horizontal Roughing: Roughing was performed using a ⅛” flat end mill at a cut feed rate of 14.667 inches/minute, leaving a stock allowance of 0.025” on the part. An offset cut pattern was used with a mixed cut direction at a stepover of 40% of the tool diameter or 0.05” for cavity/pocket areas and 25% for core/facing areas. The stepdown was set to 0.125” with depth first cut level ordering and a ramp entry of 10 degrees with arc fitting enabled. Note that the arc motions are shown in blue in the toolpath image below.

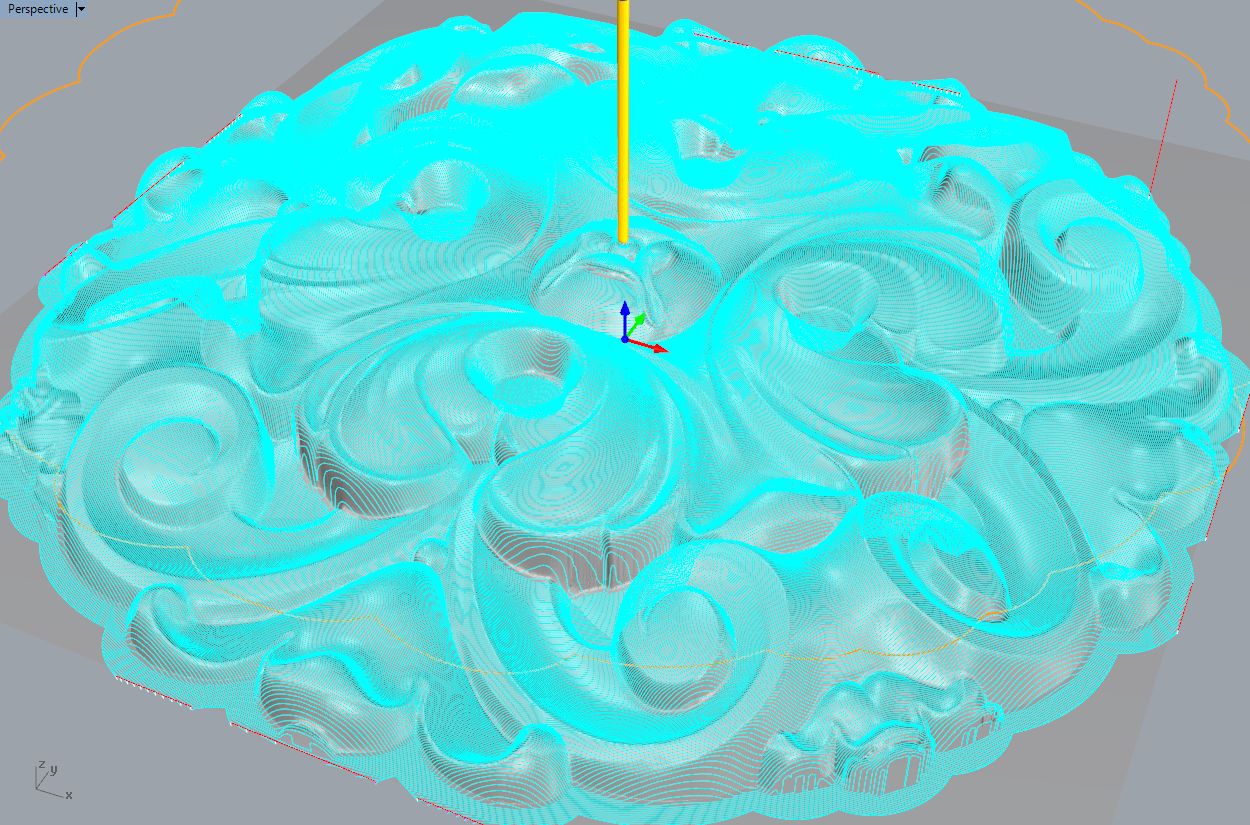

- 3 Axis Spiral Machining: Finishing begins with a 3 Axis Spiral strategy using a 1/16” ball mill with a stock allowance of zero, a climb cut direction and a stepover of 0.01”. This strategy is best suited for parts with circular features and maximizes material removal on the near horizontal areas of the part.

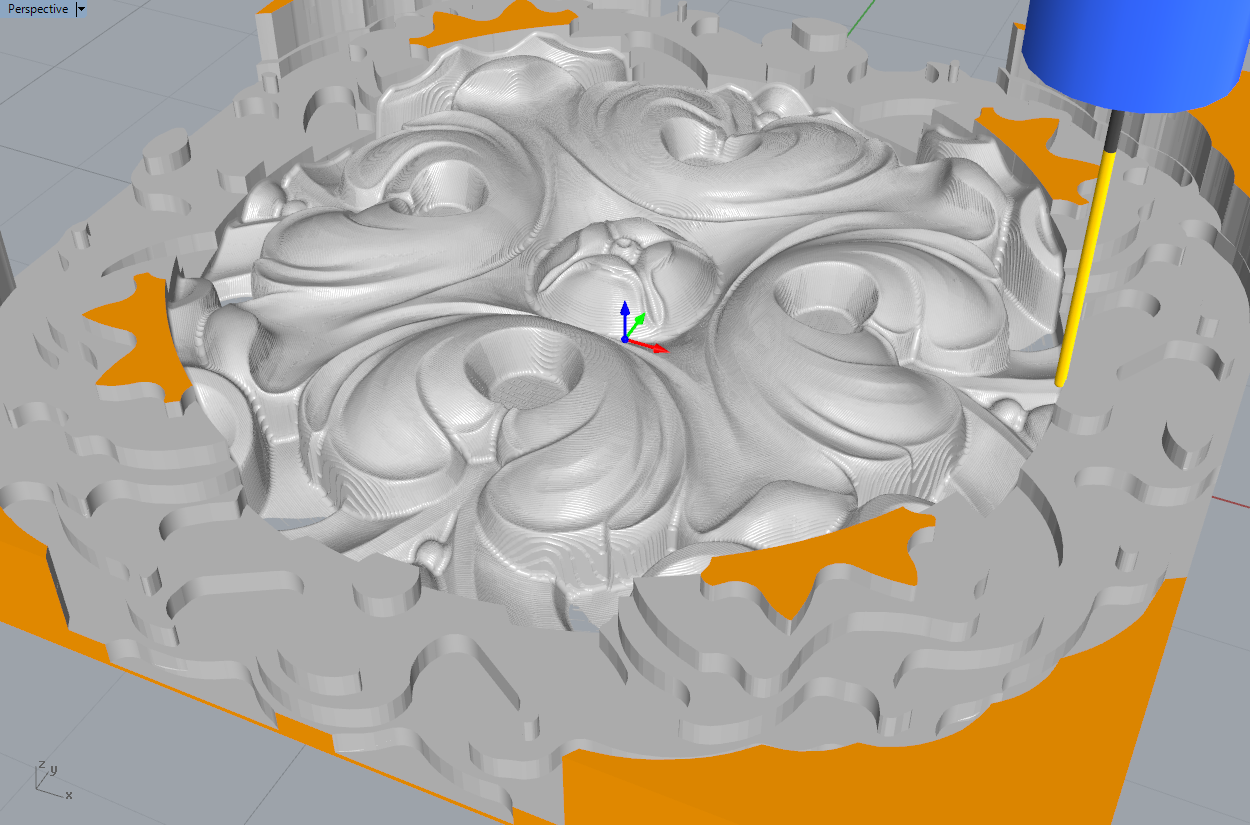

- 3 Axis Horizontal Finishing: A secondary Horizontal Finishing strategy is used that is best suited to maximize material removal at the near vertical areas of the part. Again, the stock allowance is set to zero, cut direction is set to climb with a stepover of 0.01”

|

|

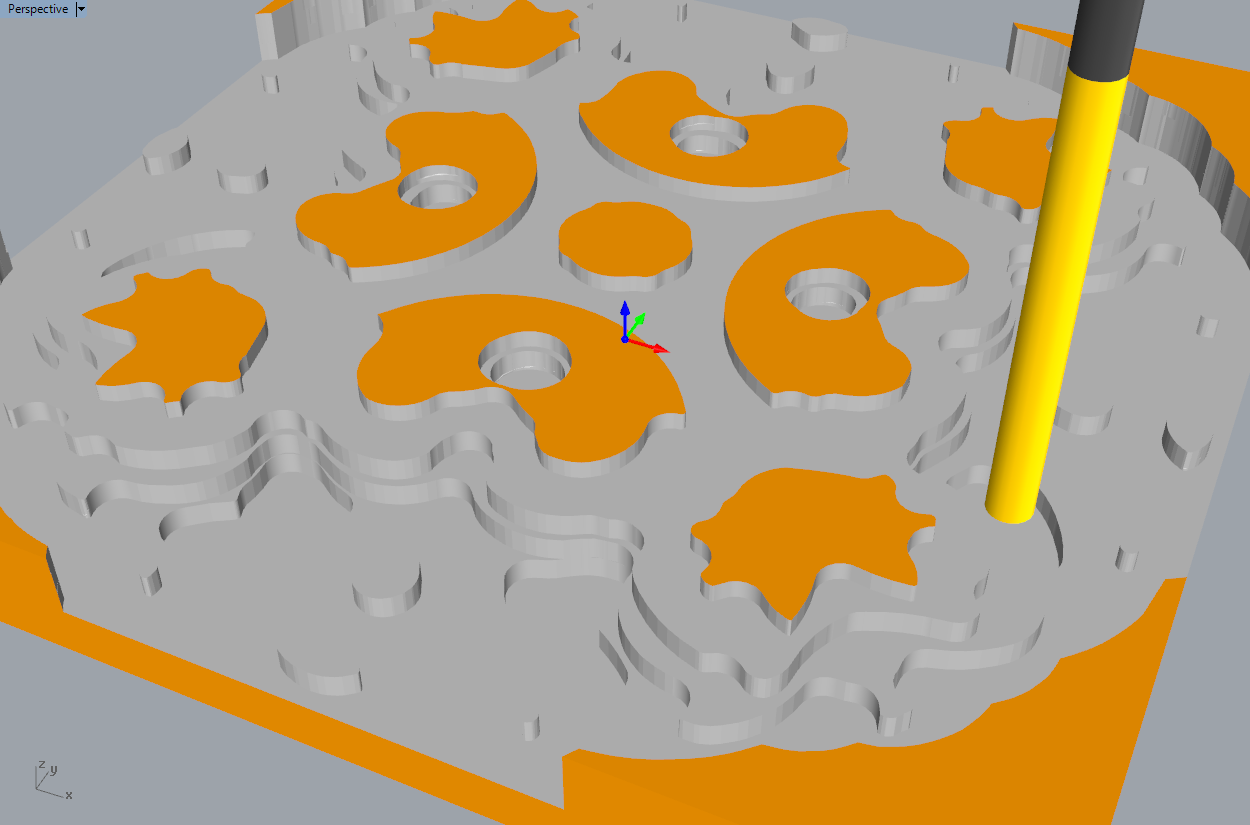

| (Left) The reduced mesh (Right) The stock model | |

|

|

| (Left) The 3 Axis Horizontal Roughing strategy (Right) The cut material simulation in process | |

|

|

| (Left) The 3 Axis Spiral Machining strategy (Right) The cut material simulation in process | |

|

|

| (Left) The 3 Axis Horizontal Finishing Strategy (Left) The cut material simulation in process | |

|

|

| (Left) The sculpted 3D model in ZBrush (Right) The actual 6” machined part from RhinoCAM toolpaths. | |

Note: The rosette that Jim designed here in ZBrush was reproduced with permission from the collection of Decorators Supply of Chicago.

More About Lohmann Woodcarving

Jim Lohmann has been practicing woodcarving by hand for the past 45 years, getting his start in the Boston area, and then moving to Chicago. Today, Jim works from his shop in Covington, Michigan, where he has been practicing his craft for the past 30 years. For more information about Jim and Lohmann Woodcarving we invite you to visit him online at digitalwoodcarving.com and these additional links:

Jim Lohmann has been practicing woodcarving by hand for the past 45 years, getting his start in the Boston area, and then moving to Chicago. Today, Jim works from his shop in Covington, Michigan, where he has been practicing his craft for the past 30 years. For more information about Jim and Lohmann Woodcarving we invite you to visit him online at digitalwoodcarving.com and these additional links: